High Capacity Cycling/Non-Cycling Refrigerated Compressed Air/Gas Dryers

Systems Than Can Handle The Toughest Demands, Or Provide New Levels of Cost Efficiency

Next Air & Gas is regarded as the industry leader in the design and manufacture of Refrigerated Compressed Air Dryers. Our dryers provide years of trouble-free service even under the harshest conditions.

Next Air & Gas’ high capacity refrigerated air dryers with the recommended pre-filter and after-filter eliminate harmful impurities and reduce the Pressure Dew Point (PDP) of the compressed air stream to a safe level, thereby preventing condensation or any accumulation of moisture in the pipelines.

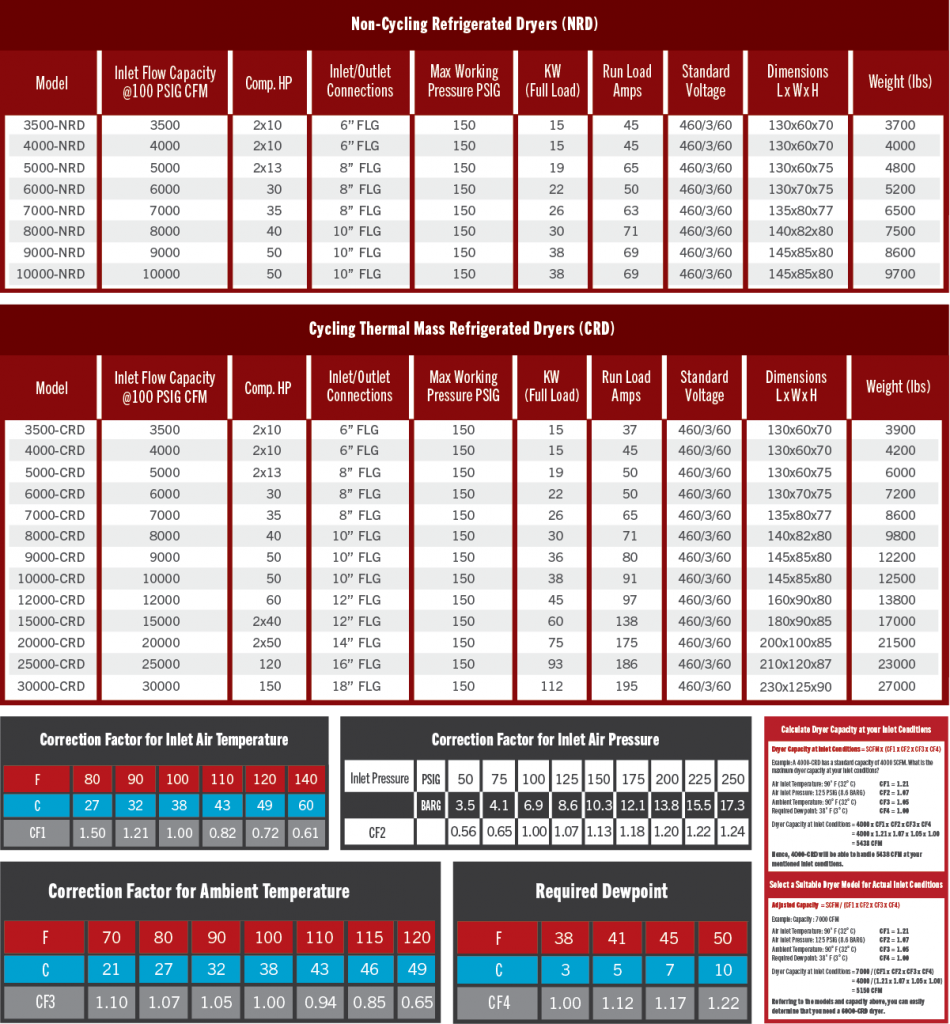

Our Cycling models provide exceptional control over process air systems and are capable of handling capacities up to 30,000 CFM in high-demand applications.

Our Non-Cycling models offer the best value. They are suited for applications that have marginal load fluctuations (e.g., constant load), and handle capacities to 10,000 CFM. With periodic maintenance and automatic drain systems, they can provide years of trouble-free service.

Standard Features

- Inlet temperature gauge

- Refrigeration suction pressure gauge

- Refrigeration discharge pressure gauge

- Status indicator lights

- Compressor ON indicator

- Standard NEMA 12 enclosure

- Single skid mounted

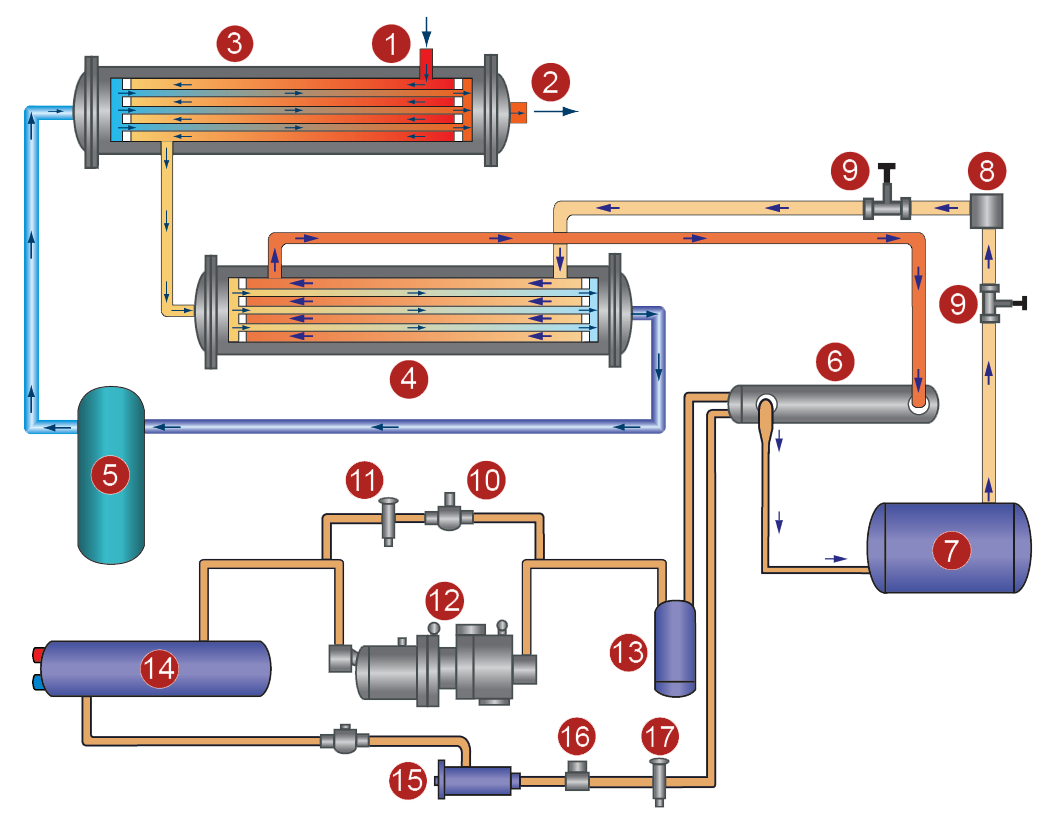

- Air-Water/Glycol heat exchanger

- Air-Air Pre-cooler/re-heater (Economizer)

- Condenser automatic water regulating valve

- Inlet temperature indicator

- Outlet temperature indicator

- Compressor sequencer (for units with multiple compressors)

- Pump sequencer (for units with duplex pumps)

- Air inlet pressure gauge

- Air outlet pressure gauge

- Zero-purge drain system

- Pump pressure gauge

- Thermal shortage temperature gauge

- Rotation protection module

- High-temperature module

- Pump failure indicator

- No-flow indicator

- Pump starter with overload protection

- Compressor starter with overload protection

- Outlet pressure indicator

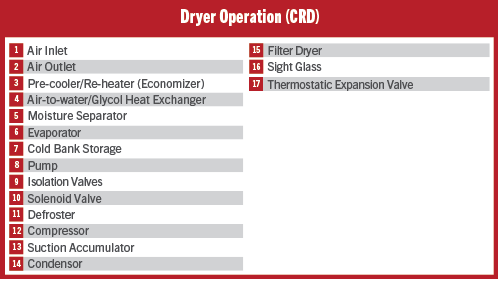

| Model | Capacity in CFM | Comp. HP | In/Out Conn. Inches | Max. Working Pressure PSIG | Full Load KW | Full Load Amps | Standard Voltage | Length | Width | Height | Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3500-NRD | 3,500 | 2 x 10 | 6″FLG | 150 | 15 | 45 | 460-3-60 | 130 | 60 | 70 | 3,700 |

| 4000-NRD | 4,000 | 2 x 10 | 6″FLG | 150 | 15 | 45 | 460-3-60 | 130 | 60 | 70 | 4,000 |

| 5000-NRD | 5,000 | 2 x 13 | 8″FLG | 150 | 19 | 65 | 460-3-60 | 130 | 60 | 75 | 4,800 |

| 6000-NRD | 6,000 | 30 | 8″FLG | 150 | 22 | 50 | 460-3-60 | 130 | 70 | 75 | 5,200 |

| 7000-NRD | 7,000 | 35 | 8″FLG | 150 | 26 | 63 | 460-3-60 | 135 | 80 | 77 | 6,500 |

| 8000-NRD | 8,000 | 40 | 10″FLG | 150 | 30 | 71 | 460-3-60 | 140 | 82 | 80 | 7,500 |

| 9000-NRD | 9,000 | 50 | 10″FLG | 150 | 38 | 69 | 460-3-60 | 145 | 85 | 80 | 8,600 |

| 10000-NRD | 10,000 | 50 | 10″FLG | 150 | 38 | 69 | 460-3-60 | 145 | 85 | 80 | 9,700 |

Next Air & Gas Performance Advantages

The performance of any dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and

desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

High Efficiency Compressors

Depending on the model, our dryers utilize high efficiency compressor designs including:

- Semi Hermetic Energy Saver Screw and Open Drive Rotary Screw Compressors

- Semi Hermetic High Performance Piston Compressors

- High Efficiency Scroll Compressors

Air Cooled Condenser

Air cooled condensers are constructed from high thermal efficiency copper tubes. Coils and aluminum fins are rated for 100 F ambient temperature.

Water Cooled Condenser

Water cooled condensers are designed according to ASME standards with carbon steel shell and copper tubes to provide adequate cooling capacity that exceeds the refrigeration demand. They are equipped with head pressure control and energy saver water regulating valves.

NEMA Electrical Enclosure

NEMA 12 enclosures are standard on all high capacity refrigerated dryers. Optional controls, monitoring systems, indicators, and NEMA 4, NEMA 4x, and NEMA 7 enclosures are also available.

Separator

With very little pressure drop, our cyclone separator strips the moisture from the chilled air and safely discharges the condensate with the use of a zero-purge loss drain.

Evaporator

Evaporators are either shell-and-tube type or brazed stainless steel plate type, and are designed for high heat transfer efficiency. Each refrigeration zone has a its own independent evaporator, so failure of one refrigeration compressor will have no effect on the other circuits.

Controller

State-of-the-art PLCs (Programmable Logic Controllers) are used for close monitoring of inlet, outlet, and dew point temperatures. Modular features make our controllers suitable for various applications, including local and remote display.