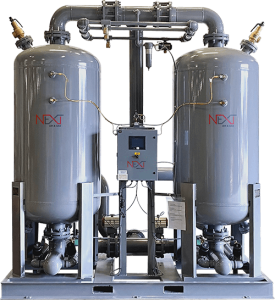

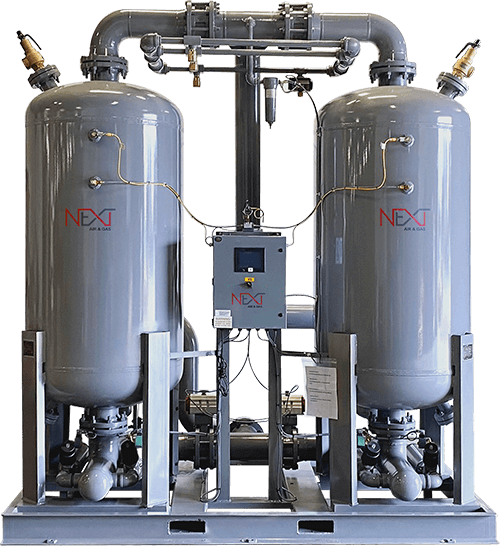

Heatless Regenerative Desiccant Dryers

Low Capital Investment. Long Life and Low Maintenance.

Next Air & Gas Heatless Regenerative Desiccant Dryers are ideal for demanding applications requiring very dry air. Our dryers offer dewpoints ranging from -400 F to -1000 F. Our heavy duty design can operate around the clock, providing years of trouble free service with minimal maintenance.

Next Air & Gas offers two lines of Heatless Regenerative Dessicant Dryers, our HHD Series, with inlet flow capacities of 80 to 5,000 CFM, and our MDA Series of Mini Desiccant Dryers with inlet flow capacities of 10 to 45 CFM.

Should you need guidance determining which type of dryer works best for your operation, our on-staff experts are happy to do an analysis and make recommendations. You can request assistance here.

Principle of Operation

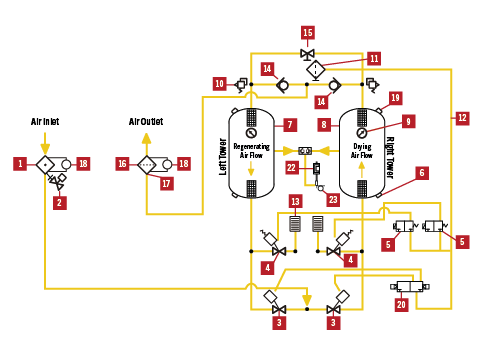

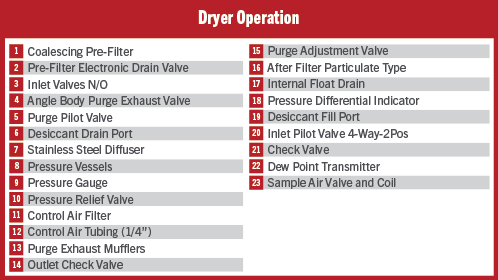

The twin tower design allows for continuous adsorption of water vapor from compressed air by using the X-PACK – a hygroscopic desiccant with high crush strength and a high surface/volume ratio. Drying is accomplished by passing compressed air through one desiccant bed adsorbing moisture while the other is being simultaneously regenerated with the expanded purge air.

Regeneration of desiccant is accomplished without the use of heat. The wet bed is dried by diverting a small portion of the super-dry air from the outlet at near atmospheric pressure. The purge flow rate is adjustable to suit the specific outlet conditions (desired dewpoint). The super dry air flows in a counter direction through the wet bed, sweeping all the water vapor previously adsorbed by the desiccant. The DDC-15 microprocessor controller monitors the automatic operation of the dryer and provides options for load management, fixed cycle and dewpoint based control.

Next Air & Gas ensures pressure equalization in the twin towers prior to switching. This prevents line surge and minimizes desiccant attrition. The tower being reactivated will be gradually re-pressurized at the end of its reactivation cycle before switchover takes place. Purge flow and de-pressurization are in a downward direction, counter flow to the drying air flow.

Industry-Standard Performance

And Exceptional Quality

Optional Features

- Special finishes for severe environments, process industries, offshore drilling rigs, etc.

- Pneumatic control timer. Eliminates need for control electric power

- NEMA 4x and explosion proof NEMA 7

- High pressure up to 10,000 PSIG

- Energy saver demand cycle control

- Optimal voltage (230/208/1/50/60)

- High dew point alarm

- Switching failure alarm

- -100 F pressure dew point

Standard Features

- On/off switch

- Optimal tower size

- Field adjustable timer cycle, 4, 10 or 15 minutes

- Pilot air filter

- Front mounted control panel

- Non-lubricated inlet valve

- High-efficiency angle body piston purge valve

- Spring load check valves

- Separate drain and fill port

- Stainless steel inlet/outlet diffusers

- Tower pressure gauge

- Purge flow valve for adjusting purge flow

- ASME code construction and stamped pressure vessels (6" diameter and larger)

- Structural steel frame with floor stand

- Pre-piped and mounted pre-filter and after-filter

- Full charge of desiccant

- NEMA 4 electrical enclosure

- Safety pressure relief valve for each tank

- Fail safe design in case of power failure: the bi-directional piston valve remains in the same position to ensure air flow through the dryer without interruption

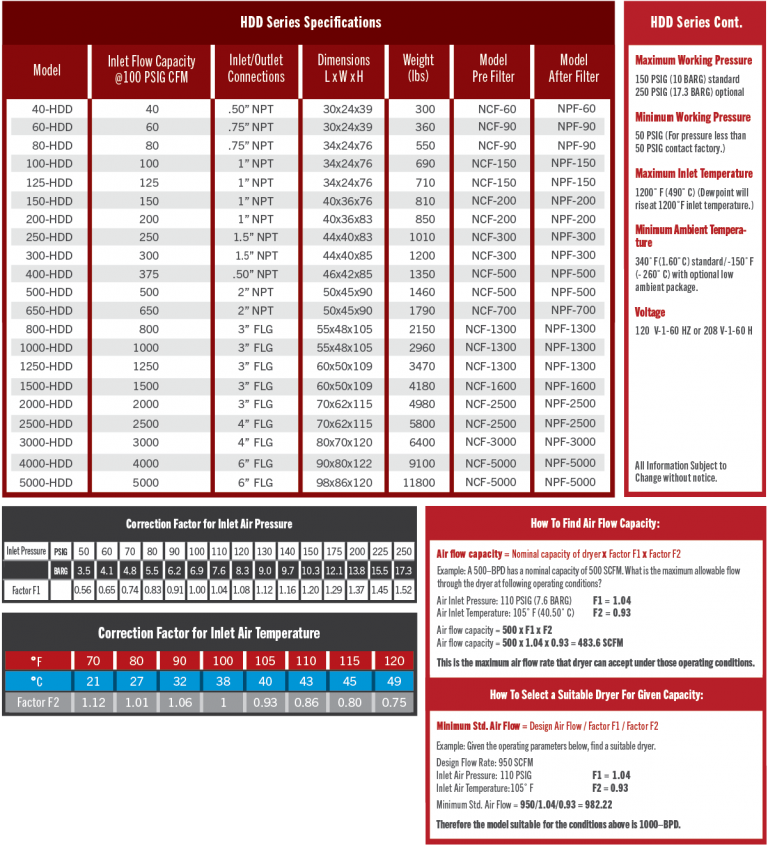

| Model No. | Inlet (CFM) | Inlet/Outlet Connections | L x W x H (inches) | Weight (Lbs) | Pre-filter | After Filter |

|---|---|---|---|---|---|---|

| 80-HDD | 80 | ¾” NPT | 34x24x76 | 550 | FTX-125 | FTP-125 |

| 100-HDD | 100 | 1” NPT | 34x24x76 | 690 | FTX-125 | FTP-125 |

| 125-HDD | 125 | 1” NPT | 34x24x76 | 710 | FTX-125 | FTP-125 |

| 150-HDD | 150 | 1” NPT | 40x36x76 | 810 | FTX-200 | FTP-200 |

| 200-HDD | 200 | 1” NPT | 40x36x83 | 850 | FTX-200 | FTP-200 |

| 250-HDD | 250 | 1 ½” NPT | 44x40x83 | 1010 | FTX-300 | FTP-300 |

| 300-HDD | 300 | 1 ½” NPT | 44x40x85 | 1200 | FTX-300 | FTP-300 |

| 375-HDD | 375 | 1 ½” NPT | 46x42x85 | 1350 | FTX-450 | FTP-450 |

| 500-HDD | 500 | 2” NPT | 50x45x90 | 1460 | FTX-600 | FTP-600 |

| 650.HDD | 650 | 2” NPT | 50X45x90 | 1790 | FTX-600 | FTP-600 |

| 800-HDD | 800 | 3” FLG | 55x48x105 | 2150 | FTX-900 | FTP-900 |

| 1000-HDD | 1000 | 3” FLG | 55x48x105 | 2960 | FTX-1500 | FTP-1500 |

| 1250-HDD | 1250 | 3” FLG | 60x50x109 | 3470 | FTX-1500 | FTP-1500 |

| 1500-HDD | 1500 | 3” FLG | 60x50x109 | 4180 | FTX-1500 | FTP-1500 |

| 2000-HDD | 2000 | 3” FLG | 70x62x115 | 4980 | FTX-3000 | FTP-3000 |

| 2500-HDD | 2500 | 4” FLG | 70x62x115 | 5800 | FTX-3000 | FTP-3000 |

| 3000-HDD | 3000 | 4” FLG | 80x70x120 | 6400 | FTX-3000 | FTP-3000 |

| 4000-HDD | 4000 | 6” FLG | 90x80x122 | 9100 | FTX-5000 | FTP-5000 |

| 5000-HDD | 5000 | 6” FLG | 98x86x120 | 11800 | FTX-5000 | FTP-5000 |

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

Electronic Controllers Provide The Information You Need

All Next Air & Gas heated desiccant regenerative dryers are equipped with the state of the art PLC controllers that regulate and monitor dryer function. A simple user interface allows the operator to quickly enter settings and monitor operations, including dewpoint selection, energy cycle, diagnostics, and more. The unit can also be connected to a remote computer.

Digital Dewpoint Transmitters Optimize Operations

The digital dewpoint transmitters are compact, reliable and continuously monitor the dryer performance. With available options, monitors can be used as indicators, alarm units or as controllers. A simple interface permits the operator to choose between multiple units, output the data to a PC, set alarm levels and do field calibration of the sensor.

Quality Desiccant Media

Next Air & Gas uses a mixture of adsorption media in its heatless range of desiccant dryers to achieve consistent dewpoint. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application. The long lasting, high crush strength media has a very high surface/volume ratio.

Super-Tough, Maintenance-Free Bi-Directional Piston Valves

These non-lubricated, high quality, high performance, bi-directional piston valves are designed to handle the most severe conditions. They require no maintenance and come with a five-year limited warranty.

Angle Body Piston Valve

These high-performance, 2-way direct acting valves are designed for reliability and durability. It uses a profiled disc in conjunction with a high-resolution compact positioner and linear feedback potentiometer to provide precise proportional flow. The stainless steel internals and a tough fiber composite actuator body, along with the use of oversized bearing and Viton® seals, make it possible to consistently provide smooth piston movement for years of trouble-free service.

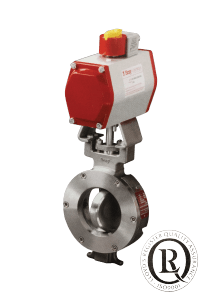

Butterfly Valves for Precise Control

These versatile, high-performance butterfly valves are used by Next Air & Gas to provide you with precision control and complete bubble-tight shut off. The digitally controlled actuators provide easy PLC interface and feature fast response time. The tongue-and-groove seat design feature ensures complete isolation of flowing media from the body and stem. Rugged and reliable, these valves are designed to provide years of trouble-free service.