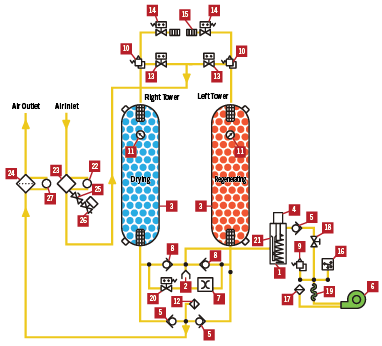

Externally Heated Dessicant Dryer

High Volume. Low Cost.

Externally Heated Regenerative Compressed Air Dryers are ideal for general

manufacturing and process industry applications. In External Heater models, purge air is heated outside the desiccant bed, then passed over the bed to regenerate it.

Next Air & Gas externally heated regenerative dryers provide a low -40º F/C pressure dew point for superior air line moisture protection, while offering the efficiency of convection-heated desiccant regeneration.

They feature:

- Isolated External Heater for extra safety

- Intelligent Valve Control for the most reliable tower cycling.

- Heatless Back-Up Mode to prevent loss of production in the event of heater failure or maintenance.

Should you need guidance determining which type of dryer works best for your operation, our on-staff experts are happy to do an analysis and make recommendations. You can request assistance here.

Industry-Standard Performance

And Exceptional Quality

Optional Features

- Pre-piped and mounted pre-filter and high temp after-filter

- Mounted filter with 3-valve bypass

- Duplex pre-filter and duplex after-filter with 9-valve bypass

- Energy save demand cycle control with digital dew point display and adjustable setpoint

- Tank insulation with safety jacket

- Stainless steel control air tubing

- Visual moisture indicator

- NEMA-7 Class I, DiV.II Group C & D explosion-proof electrical enclosure

- Sub-zero package (ambient temperature down to -20˚F)

- NEMA-4X stainless steel electrical enclosure(waterproof, dustproof & corrosion resistance)

- Low-ambient package (+20˚ to +30˚F)

- 400/380 volt 3-phase (50HZ) control power

- 575 volt 3-phase (60HZ) control power

- Fusible disconnect switch

Standard Features

- State-of-the-art PLC controller with color touch screen HMI

- High-quality, direct drive, oil-free regenerative blower

- Low watt/density heater

- High-performance, non-lubricated pneumatic butterfly valve (800CFM & up)

- High-quality, non-lubricated pneumatic piston valve (200-600CFM)

- State-of-the-art, flow activated, high-temperature check valve (800CFM & up)

- Stainless steel inlet/outlet diffuser

- Visual alarm status

- Desiccant towers designed and constructed in accordance to ASME & CRN code

- Pressure vessels feature 200PSIG (up to 1500CFM) and 150PSIG (2000CFM & up)

- UL/CUL certified electrical

- Full charge of desiccant (2000CFM & up shipped separately)

- NEMA-4 waterproof & dustproof electrical enclosure

- ASME and CRN certified safety relief valve for each pressure vessel

- Highest quality desiccant (Made in USA)

- Dryer hour meter

- Dryer service hour meter with alarm and reset

- Dryer common alarm with history

- Dryer back-up heatless mode in case of emergency

- Dryer heater back-up safety contactor with MSP switch

- Failure-to-shift alarm in case of valve or pressure failure

- 460 volts, 3-phase 60HZ control power

- Fully field-adjustable heater temperature setpoints

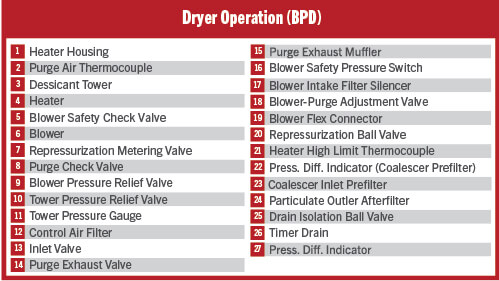

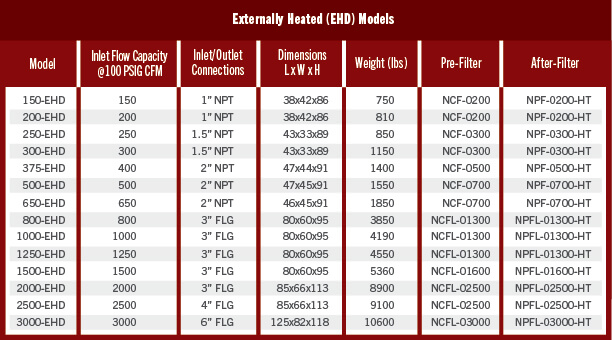

| Model No. | Inlet Flow | Inlet/Outlet Connections | Dimensions L x W x H (inches) | Weight (lbs) |

|---|---|---|---|---|

| 150-EHD | 150 | 1” NPT | 34x35x76 | 890 |

| 200-EHD | 200 | 1” NPT | 34x35x76 | 910 |

| 250-EHD | 250 | 1 1/2” NPT | 40x40x76 | 1110 |

| 300-EHD | 300 | 1 1/2” NPT | 40x40x83 | 1250 |

| 375-EHD | 375 | 2 1/2” NPT | 50x44x85 | 1400 |

| 500-EHD | 500 | 2” NPT | 50x44x90 | 1600 |

| 650-EHD | 650 | 2” NPT | 50x44x90 | 1900 |

| 800-EHD | 800 | 3” FLG | 70x55x105 | 2900 |

| 1000-EHD | 1000 | 3” FLG | 70x55x105 | 4190 |

| 1250-EHD | 1250 | 3” FLG | 80x60x109 | 4550 |

| 1500-EHD | 1500 | 3” FLG | 80x60x109 | 5360 |

| 2000-EHD | 2000 | 3” FLG | 100x85x110 | 6900 |

| 2500-EHD | 2500 | 4” FLG | 100x85x110 | 8100 |

| 3000-EHD | 3000 | 4” FLG | 110x89x120 | 9400 |

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and

desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

Quality Desiccant Media

Next Air & Gas uses a mixture of adsorption media in its heatless range of desiccant dryers to achieve consistent dewpoint. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application. The long lasting, high crush strength media has a very high surface/volume ratio.

Electronic Controllers Provide The Information You Need

All Next Air & Gas heated desiccant regenerative dryers are equipped with the state of the art PLC controllers that regulate and monitor dryer function. A simple user interface allows the operator to quickly enter settings and monitor operations, including dewpoint selection, energy cycle, diagnostics, and more. The unit can also be connected to a remote computer.

Digital Dewpoint Transmitters Optimize Operations

The digital dewpoint transmitters are compact, reliable and continuously monitor the dryer performance. With available options, monitors can be used as indicators, alarm units or as controllers. A simple interface permits the operator to choose between multiple units, output the data to a PC, set alarm levels and do field calibration of the sensor.

High-Efficiency Blower

High-Efficiency Blower The centrifugal blower is sized optimally to provide a continuous stream of air to the heater for regeneration. The blower is equipped with an intake filter, a muffler for quieter operation, and check and relief valves for high-pressure safety.

Angle Body Piston Valve

These high-performance, 2-way direct acting valves are designed for reliability and durability. It uses a profiled disc in conjunction with a high-resolution compact positioner and linear feedback potentiometer to provide precise proportional flow. The stainless steel internals and a tough fiber composite actuator body, along with the use of oversized bearing and Viton® seals, make it possible to consistently provide smooth piston movement for years of trouble-free service.

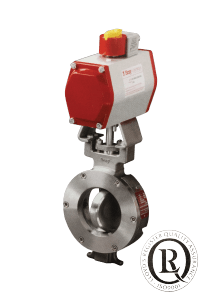

Butterfly Valves for Precise Control

These versatile, high-performance butterfly valves are used by Nortec to provide you with precision control and complete bubble-tight shut off. The digitally controlled actuators provide easy PLC interface and feature fast response time. The tongue-and-groove seat design feature ensures complete isolation of flowing media from the body and stem. Rugged and reliable, these valves are designed to provide years of trouble-free service.

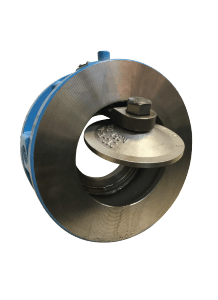

State-of-the-Art Check Valve

High-temperature, wafer-combination swing check valves are flow activated. The elliptical shape of the inlet port accelerates the inlet media through the valve. The disc’s angle and shape allows the air to travel faster around the disc, thus creating lift like an aircraft wing, and opens the valve in full position even at low flow rate.