NCS Series (25-1,000 CFM)

Cyclone Separator

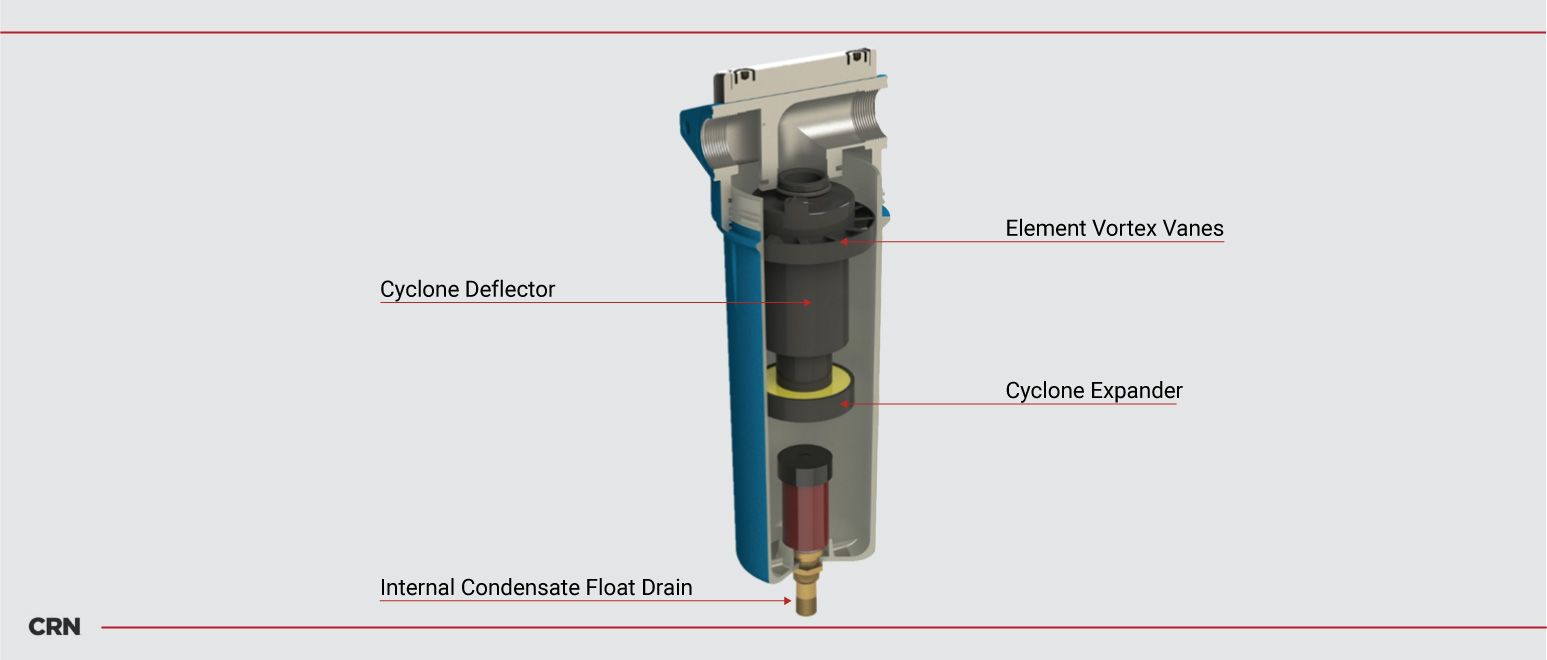

Next’s NCS cyclone water separators provide the most cost-effective method to remove entrained moisture from compressed air with minimum potential for re-entrainment. Designed and engineered compressed air or technical gasses in industrial applications. The three-part housing with vortex vanes offers low differential pressures at high flow rates. An engineered insert in the cyclone head creates a centrifugal force that pushes liquid and particulate to the housing wall. Friction within the housing causes the liquid and particulate to lose a portion of its kinetic energy and drop out of the higher circulating air stream. The collected condensate is removed by either an internal float drain or an electronic zero loss drain, while the separated compressed air or gas exits downstream.

Benefits

- High liquid removal efficiencies at all flow conditions

- Cost effective

- Low maintenance

- Very low differential pressure

- Removes rust and pipe scale

NCS Series Features

- Eliminate corrosion, damage to tools and machinery downtime with efficient bulk water removal

- Eliminate 99% of liquids in your compressed air or gas system, improving your processes and reducing costly downtime

- Suited for variable speed compressors

- Tested in accordance with ISO 8573-9

- Housing manufactured from die cast aluminum housing & bowl

- Housing & bowl are chromo phosphate and externally powder coated ensuring long lasting corrosion protection

- CRN APPROVED

- Flow-optimized design

- Engineered cyclone element

- Stop-lock housing & Bowl

- Low pressure drop

- High efficiency precision over a broad flow range

- Prevents separator from being opened while under pressure.

- Durable design

Operating Pressure

- 20 to 232 Psig

- 1.5 to Bar

Flow Rates

- 25 – 1000 SCFM

Inlet /Outlet Connections

- 1/2” To 2-1/2” NPT

Operating Temp Range

- 35 To 176°F

- 2 To 80 °C

Pressure Loss at Rated Flow

- .7 psig

- .05 bar

Material

- Chromo phosphate Aluminum

ISO Air Quality Class (solids, water, oil)

- ISO Class 8573-9

Certified

- CRN

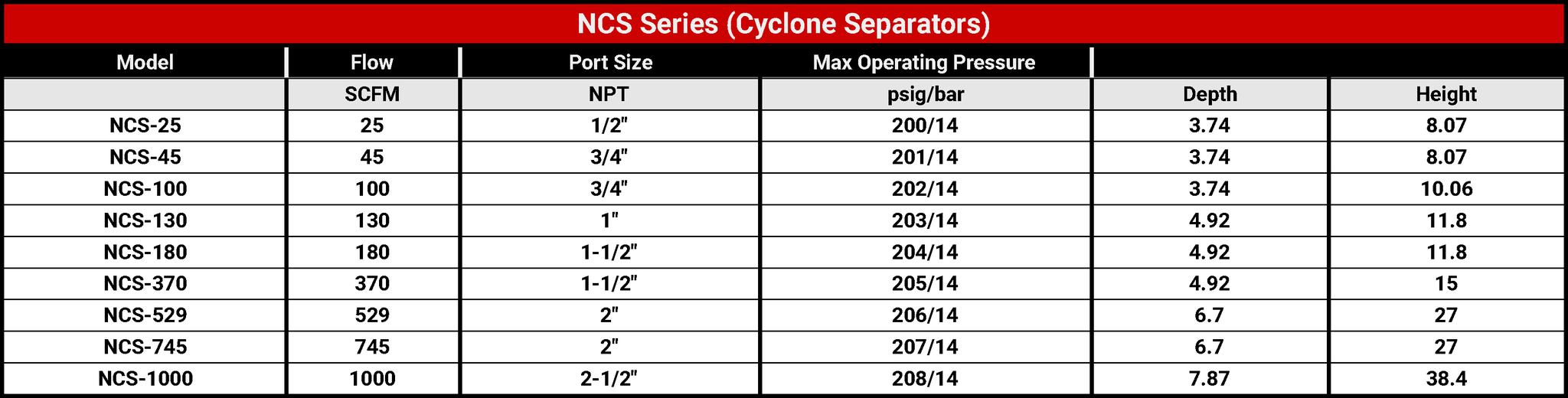

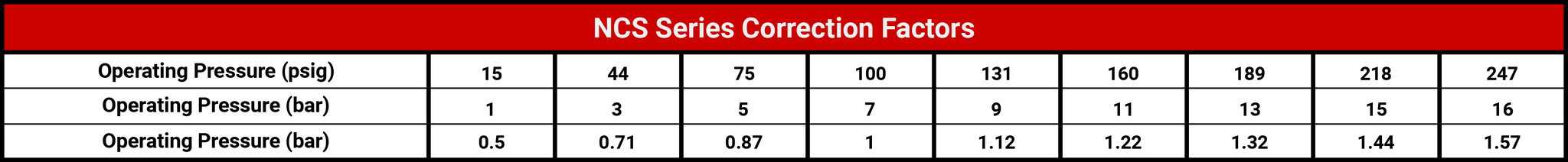

NCS Series Range

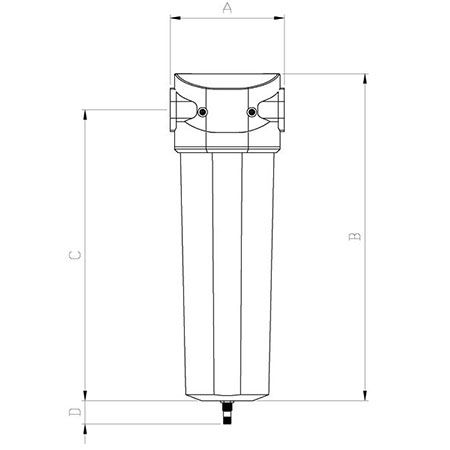

Correction Factors

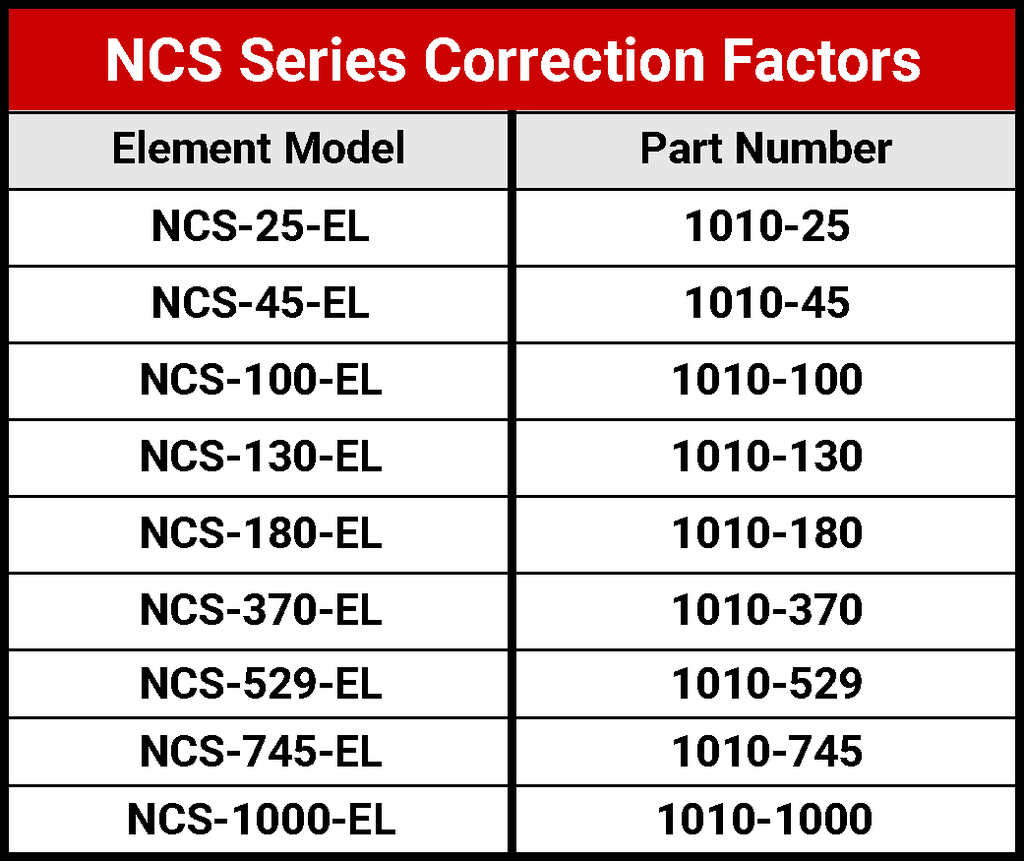

NCS Separator Element

- The cyclone profile increases the efficiency of the NCS separator line.

- The new structure offers the possibility to enter the cyclone cartridge for inspection and maintenance.

- Engineered using the latest fluid dynamic principles to optimize liquid removal efficiency.

- The vortex arrester ensures that the separated liquid cannot re-enter the air or gas stream, greatly improving drainage efficiency.

NCS Options

The Next condensate drain series, drain without the loss of compressed air, guarantees a secure and economical drainage of condensate for any application.

The sizing of the condensate drains matches perfectly the volume flows and guarantees secure drainage even with higher condensate volumes.

Electronic Zero Loss Drain

NBM- Series

Timer Condensate Drain

NTD- Series

Mechanical Zero Loss Drain

NWH- Series

External Gravity Fed Zero Loss Drain

NEFD- Series

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Principle of Operation

The complex design of Next’s NCS Separator utilizes and established principle of centrifugal force to separate entrained liquid.

- An engineered insert in the cyclone head creates a centrifugal force that pushes liquid and particulate to the housing wall.

- Friction within the housing causes the liquid and particulate to lose a portion of its kinetic energy and drop out of the higher circulating air stream.

- The collected condensate is removed by either an internal float drain or an electronic zero loss drain, while the separated compressed air or gas exits downstream.

Overview

Next Air & Gas Performance Advantages

Connections

More port sizes (1/2”-2-1/2”)are available to match both pipe size and system flow rate giving additional customer choice.

Stop Lock Feature

Stop lock design creates perfect performance seal to ensure efficiency.

Fully Corrosion Protected

Anodized cast aluminum and powder coated with epoxy finish for full corrosion protection.

Compact & Light Weight

Advanced housing and element design prove a smaller, more compact and lightweight filter which is efficient and easy to maintain.

Stainless Auto Condensate Drain

Specially designed stainless-steel auto drain system protects from corrosion and other contaminants.

Why Moisture Separators are important

Bulk water separation is a critical early step in the compressed air treatment process. Water separators remove large diameter water droplets from the air stream, enhancing the performance and durability of downstream treatment equipment such as coalescing filters and air dryers. Water separators are typically installed immediately downstream of coolers and wet receiver tanks.

Next’s Compressed Air & Gas Separation

The need to effectively and efficiently dry, filter and separate compressed air & gas cannot be overemphasized. Ineffective purification can lead to system and / or equipment damage and product spoilage. Inefficient purification can lead to unnecessarily high operating and maintenance costs.

With over 40 years of compressed air purification experience behind us, Next has developed an extensive line of air / gas separation products with a range of efficiencies and optional features to cost effectively meet any of your needs. Our pre-filters and post-filters can be configured to suit the requirements of your specific application.

- Dust Particles (from Ambient air and/or desiccant)

- Liquid Water and Moisture Vapor

- Liquid Oil and Oil Vapor

- Hydrocarbon Vapor

- Rust Particles

- Pipe Scale

- Acidic Condensates