NFG Series (1,900-10,000 CFM)

High-Capacity Flanged Filters

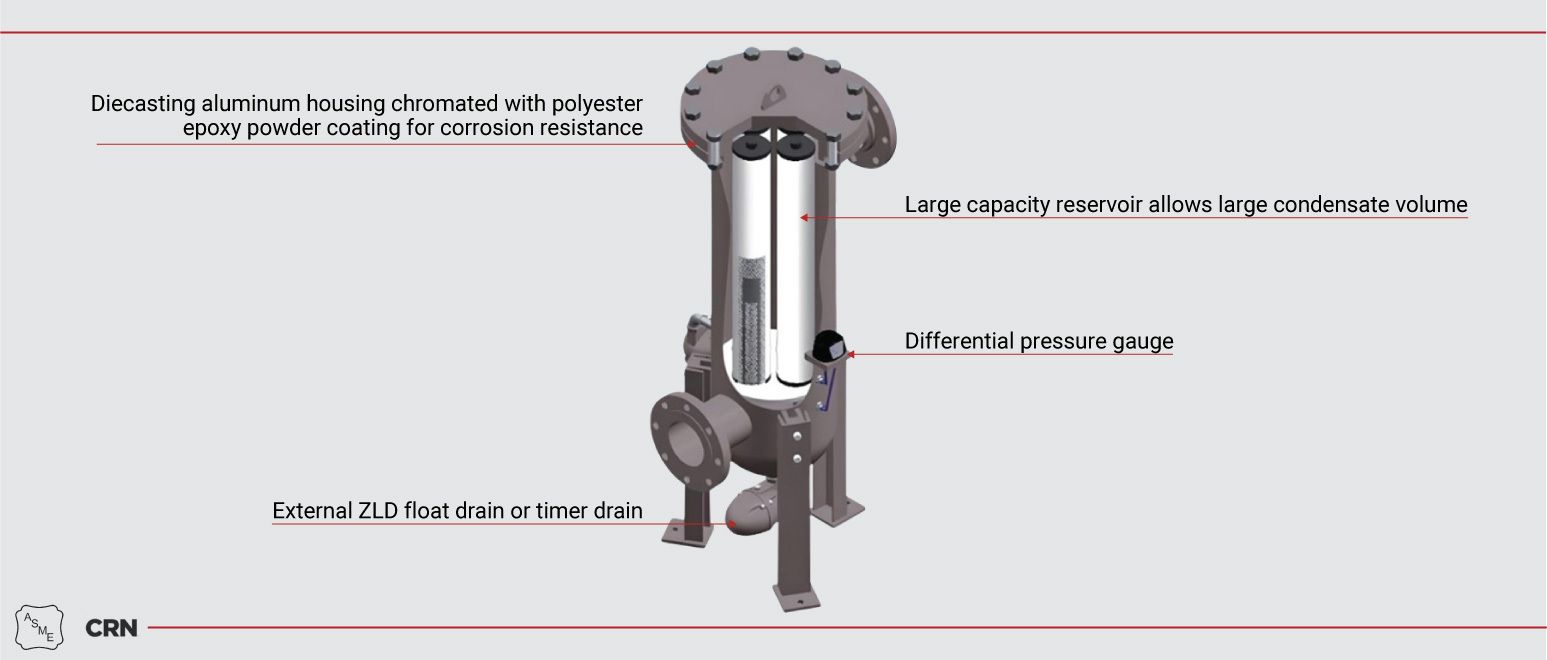

The Next NFG series range of high-capacity flanged filters are fabricated from quality carbon steel and are painted with a 2-part epoxy marine grade paint for optimum corrosion resistance. The NFG Line encompasses connections from 4” to 10” and rated flows from 1,900-10,000 SCFM.

Built in accordance with ASME VIII and carrying both a U-stamp and CRN number, these filters fit a wide range of high flow industrial applications. The Unique design has stainless steel internal parts, tie rod element connections, dual drain connections, and a side mounted differential pressure gauge with dual visibility.

- Engineered for energy efficiency – helps reduce operating costs

- Durable Housing construction for corrosion resistance

- Broad filtration from general purpose to highly stringent applications

- Optimized air flow design to help increase efficiency and reduce pressure loss

- Built for reliable and easy maintenance

The Next range of compressed air filters is designed from the outset to meet current and forthcoming requirements for compressed air quality. Using aerospace technology, Next has optimized the flow path through the housing and element, significantly reducing air turbulence and pressure losses. Providing an optimal flow path is key to reducing pressure drop and system operating costs.

NFG Series Features

- The air filters have four (4) ranges of efficiencies, removing contaminants as small as 0.01 micron at up to 200 psi 4”- 10” FLG

- Elements are assembled with a tie rod system

- Two external timer drains on pre filter for maximum drainage

- Unique design for pre-separation zone

- Strong welded design

- CRN & ASME stamped

- Design for hassle free maintenance

- Differential pressure gauge

- Filter combinations are configured to meet specific application requirements

- Filters comply with pressure equipment directives and perform as per related ISO 8573 standards

- Filters are equipped with differential pressure gauges for ease of maintenance and energy efficiency

- Superior filtration from 1 micron to .01 micron

- Durable element construction

- Efficient drain layer ensures continued performance after optimal element change periods

Max Operating Pressure

- 200 PSIG

- 14 Bar

FLOW RATES

- 1,900 – 10,000 SCFM

CONNECTIONS

- 4” TO 10” FLG

Max Operating Temp Range

- 176 °F

- 80 °C

Material

- B31.3 Welded Carbon Steel

ISO Air Quality Class (solids, water, oil)

- ISO Class 8573-1

Certified

- CRN

- ASME

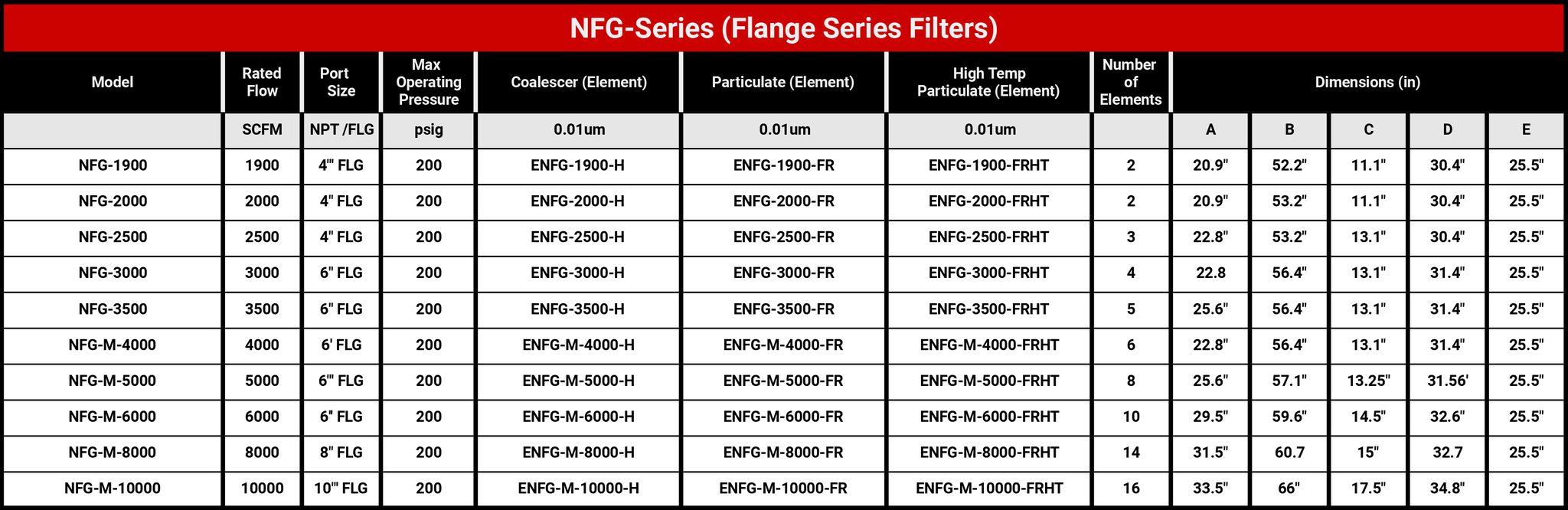

NFG Series Range

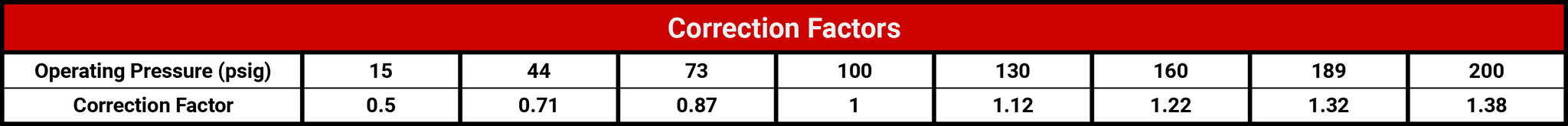

Correction Factors

For maximum flow rate, multiply model flow rate by the corresponding working pressure correction factor.

Correction Sample:

If a compressor delivers 3000 scfm at 160 psi please choose your filter model as follows: (3000 scfm / 1.22) =2460 scfm, Therefor a NFG-2500 would be needed.

Notes:

- Activated carbon must not operate in oil saturated conditions

- Activated Carbon elements should be replaced periodically to suit the application but must be changed at least every six months for efficient use

- Activated Carbon will not remove certain gasses including carbon monoxide and carbon dioxide

- Flow Rates are based on a 100-psig operating pressure, for flows at other pressures use the above correction factor table

- All filters are suitable for use with mineral and synthetic oils.

- Other standards for flanged connections are available

- Direction of airflow, inside to out, through the filter element

NFG Elements

Particulate: F and FR Elements

High Efficiency filters remove particles to 1 micron, including coalesced liquid water and lubricants

- Maximum Remaining aerosol content after filtration 0.5 ppm at 70°F (21°C)

- Media Type

- Pleated

- Efficiency Performance:

- (F) 1 micron & 0.5 ppm carryover

- (FR) Reverse 1 micron & 0.5ppm carryover

- Flow Direction

- (F) In-to-Out

- (FR) Out-to-In

- Dry Pressure Drop (psig)

- (F) 0.6

- (FR) 0.35

- Wet Pressure Drop (psig)

- (F) 1.2

- (FR) 0.6

- ISO Class

- Class 2: ISO8573-1

- Type of Filtration

- Particulate

High Efficiency Coalescing: H and HR Elements

- Maximum filtration to remove particulate down to 0.01 micron, including water and oil aerosols. Maximum remaining oil aerosol content of 0.01 ppm at 70°F (21°C), when used with Next particulate filters.

- Media Type

- Pleated

- Efficiency Performance:

- (H) 1 micron & 0.01 ppm carryover

- (HR) Reverse 0.01 micron & 0.5ppm carryover

- Flow Direction

- (H) In-to-Out

- (HR) Out-to-In

- Dry Pressure Drop (psig)

- (H) 1.2

- (HR) 4.5

- Wet Pressure Drop (psig)

- (H) 2.3

- (HR) 0.7

- ISO Class

- Class 1: ISO8573-1

- Type of Filtration

- Coalescing

Vapor Removal: C Elements

- Filters with activated carbon remove lubricant and hydrocarbon odors

- Remaining vapor content is less than 0.003 ppm (excluding methane)

- This filter installation should always be preceded by high efficiency filter grades

- Media Type

- Granule

- Efficiency Performance:

- 0.01 micron & .003 ppm carryover

- Flow Direction

- Out-to-In

- Dry Pressure Drop (psig)

- 2.3

- Wet Pressure Drop (psig)

- 2.3

- ISO Class

- Class 1: ISO8573-1

- Type of Filtration

- Carbon

High Temperature: FRHT & HT Element

- Filters are available for temperatures up to 350°F (176.6°C)

- FRHT- High efficiency particulate filter elements.

- Media Type

- Pleated

- Efficiency Performance:

- High Temperature Reverse 1 micron & 0.5 ppm carryover

- Flow Direction

- Out-to-In

- Dry Pressure Drop (psig)

- 0.35

- Wet Pressure Drop (psig)

- 0.6

- ISO Class

- Class 2: ISO8573-1

- Type of Filtration

- Coalescing

Ultra Filter: U Element

- For sensitive and high-end applications including pharmaceutical grade, Next offers the Ultra Filter, an absolute high efficiency particulate filter. (0.01 Micron Absolute)

- Media Type

- Wrapped

- Efficiency Performance:

- 0.01 micron absolute

- Flow Direction

- Out-to-In

- Dry Pressure Drop (psig)

- 5

- Wet Pressure Drop (psig)

- absolute

- Type of Filtration

- Particulate

Filter Media Designed for Compressed Air

High quality compressed air filtration starts with selecting the correct filter media. Next uses superior-quality filter media with a new hybrid technology. Our elements stop the perpetual discussion about the use of filter media with or without binders because they are layered with body types, tailored to the filtration task. This neutralizes the inherent disadvantages and, as a result, retains the advantages of both types. The fine filter media is protected on both sides using a supporting fabric to increase both the stability and reliability.

Pleated Filter Elements

Pleated filter elements provide significantly greater filtration area than non-pleated. The higher filter area provides more void space for holding contaminants which reduces the differential pressure caused by retention of solid particles. The service life of the filter element increases proportionally which results in operating and maintenance cost savings.

Incorporated Drainage Media

The filter and drainage media are supported between two stainless steel supporting cylinders, eliminating any potential detachment of the filter media. The drainage media is located inside the filter element, eliminating potential handling damage. The stainless-steel cylinders have big, diamond-shaped openings for optimum flow conditions. Compared to punch-hole versions, their contribution to differential pressure is much lower and they are much more environmentally friendly because they are made from expanded sheet metal, i.e. without metal scrap.

Two-stage dry type Separation

During dry-type separation without-to-inside flow through the filter elements, the drainage media functions as a pre-filter stage, preventing coarse contaminants from entering the fine filter media. As a result, the differential pressure caused by contaminants is reduced and the service life of the filter is extended. As an additional advantage, the filter elements can also be used for wet type filtration.

Abrasion-free Activated Carbon Filter with 100% Activated Carbon

Both the filter element type and the cartridge type contain pure activated carbon granulate. The increased filling quantities contribute to a high separation performance and a long service life. Both the elements and the cartridges have an integrated general purpose filter element which significantly reduces the abrasion particles of the activated carbon. As a result, downstream dust filtration is not required, reducing installation, operation and maintenance costs.

NFG Series Options

Filter Skid Islands

Three Valve Bypass Skid

Stainless Steel Control Air Tubing

The Next condensate drain series, drain without the loss of compressed air, guarantees a secure and economical drainage of condensate for any application.

The sizing of the condensate drains matches perfectly the volume flows and guarantees secure drainage even with higher condensate volumes.

Electronic Zero Loss Drain

NBM- Series

Timer Condensate Drain

NTD- Series

Mechanical Zero Loss Drain

NWH- Series

External Zero Loss Float Drain

NFD- Series

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

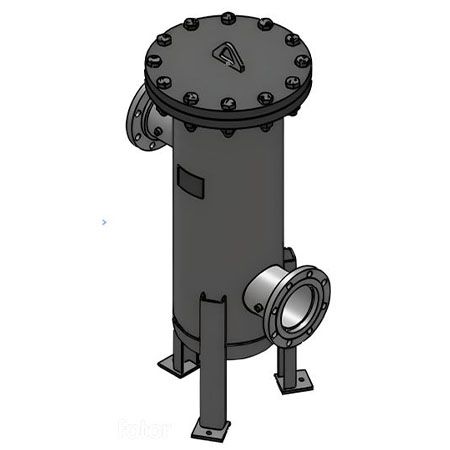

Open View

Next Air & Gas Performance Advantages

Rugged / Efficient Design

The NFG Series Flanged Filters are designed to be durable and efficient. Each NFG comes standard with a welded lifting lug for efficient movability.

Welded Filter Legs

The NFG series Flange Filters incorporate B31.3 welded filter legs with floor mounting pads. Constructed in heavy duty carbon steel.

Deep Bed Pleating

For particle and aerosol removal, deep bed pleating provides 450% more filter media than an ordinary element, giving a larger filtration area, lower flow velocities, increased dirt holding capacity, lower running costs and a more compact filter element. Graded density further improves filter life and overall performance.

Differential Pressure Gauge

A high-quality differential pressure indicator is used to identify pressure differential.

Condensate Drains

Each NFG-PRE Filter comes standard with dual timer drain condensate drains or an NFD external float drain. NFG-POST Filters come standard with dual manual drains.

Flanged Filter Connections

The NFG Series Flanged filters offer port sizes from 4” to 10”.

Next’s Compressed Air & Gas Separation

The need to effectively and efficiently dry, filter and separate compressed air & gas cannot be overemphasized. Ineffective purification can lead to system and / or equipment damage and product spoilage. Inefficient purification can lead to unnecessarily high operating and maintenance costs.

With over 40 years of compressed air purification experience behind us, Next has developed an extensive line of air / gas separation products with a range of efficiencies and optional features to cost effectively meet any of your needs. Our pre-filters and post-filters can be configured to suit the requirements of your specific application.

- Dust Particles (from Ambient air and/or desiccant)

- Liquid Water and Moisture Vapor

- Liquid Oil and Oil Vapor

- Hydrocarbon Vapor

- Rust Particles

- Pipe Scale

- Acidic Condensates