Company

About Us

Next AIR & Gas is a global provider of air & gas treatment and gas generation products to distribution and end users worldwide. With over 30 years of experience in dehydration technology, they have supplied tens of thousands of drying systems to customers worldwide. This solid foundation of expertise and experience has led Next’s evolution into gas generation, developing products, systems and technology solutions for environmentally responsible purification, dehydration, separation and filtration equipment for gasses and compressed air. Next designs, engineers and manufacturers innovative products that dehydrate moisture molecules within compressed air and gas.

Company Overview

Foundation

- Founded in 2023 by Mike Zarif an innovator in compressed air treatment. Acquired Xebec’s North American Research & Development assets . Including his former company (Nortec).

- Mike Zarif has been a pioneer in the compressed air treatment industry for decades. Founding companies such as Aircel Corporation , Nortek-Belair, and Nortec. In addition, to offering his engineering designs to globally known compressed air manufacturers.

Who Are We Today?

- Next Air & Gas is the next chapter in the long line of Zarif legacy companies, With a focus on innovation by developing cleaner and more technologically advanced air & gas products.

- Next today is a compressed air & gas treatment, generation, purification, cooling and filtration company that develops, designs and manufactures air & gas purification products for industrial applications

- Next is a technology leader in adsorption & refrigeration technology with more than 10,000+ units deployed worldwide that carry M. Zarif’s designs.

Facilities

- Headquartered in the foothills of Tennessee, USA. Next Air & Gas LLC. Operates out of 2 manufacturing facilities totaling (45,000 sqft) with additional land and partnered satellite facilities allocated for future growth.

Capabilities At A Glance

Business Model

- SYSTEMS: Design and build systems that dehydrate, purify and generate compressed air & gas.

- ECOSYSTEM: Setup, design and expand complementary product ecosystems in compressed air & gas

- SUPPORT: Industrial products, parts, service and operational support.

Markets Served

Product Segments

- Industrial Compressed Air & Gas Treatment

Industrial dehydration equipment , Parts & Service

- Industrial Gas Generation

Nitrogen and oxygen generation via PSA, Membranes

- Clean Technology

Tailored industrial purification equipment for air & gas

Mission & Values

Next and its legacy companies have always kept an identical mission and values throughout the decades. We believe these principles have shaped the foundational success of our endeavors and products.

Mission Statement:

Our Mission is to generate technological advancements in air & gas treatment by providing innovative solutions and products to the compressed air industry. We are dedicated to pushing the limits of what can be accomplished and expanding our mindset of what can be accomplished in air & gas treatment design and capabilities.

Vision Statement:

Our vision for this next chapter of our legacy is to continue being a global leader in the field, known for our relentless pursuit of innovation, exceptional quality, and unwavering commitment to our customers. We aim to redefine the technology used in compressed air dryers and to set a new standard in the industry.

Values & Beliefs:

- Customer Centricity: We put our customers’ voice and needs at the core of everything we do. We listen to their needs, understand their challenges, and deliver solutions that exceed their expectations. Their success is our success.

- Innovation: We embrace a culture of continuous innovation, pushing boundaries and exploring new frontiers. We foster creativity, encourage fresh ideas, and constantly adapt to stay ahead in a rapidly evolving world.

- Excellence: We strive for excellence in all aspects of our work. We set high standards and continuously challenge ourselves to achieve them. We take pride in our craftsmanship, attention to detail, and unwavering commitment to quality.

- Collaboration: We believe in the power of collaboration and teamwork. We foster an inclusive environment that values diverse perspectives, encourages open communication, and promotes mutual respect. Together, we achieve more.

- Integrity: We conduct ourselves with the utmost integrity, honesty, and transparency. We honor our commitments, act ethically, and take responsibility for our actions. Trust is the foundation of our relationships, both internally and externally.

- Sustainability: We are committed to environmental and social responsibility. We strive to minimize our ecological footprint, promote sustainable practices, and contribute positively to the communities we operate in. We believe in creating a better future for generations to come.

Manufacturing

Next air & gas and its legacy companies has earned a remarkable reputation based on decades of innovating in air treatment, a wide range of high-quality compressed air & gas treatment products. As a pioneer in the process of mass manufacturing air dryers, we pride ourselves on being able to provide these products at a better on-time delivery than the rest of the market. Our tested and proven manufacturing techniques and processes enhance more than 30+ years of direct experience in manufacturing and engineering of compressed air systems.

Pillars of Performance

Throughout the years and our many endeavors, the fundamental principles of our culture and mindset towards design and manufacturing of our products have never changed . We believe that our success in this industry drivers from our fundamental “Pillars of Performance and Manufacturing Principles”.

- QUALITY: Quality and durability are the foremost goals of all our products. We specifically design and manufacture our products to not only provide exceptional performance but to ensure that every product can withstand the harshest environments and stand the test of time.

- SERVICE: We believe that our products are a representation of our knowledge and experience in the field. Through this we will always be committed to aid and pass on our knowledge to better help not only our customers but also the industry towards growth.

- INNOVATION & DESIGN: At Next, perfection is never to be looked at as something that can be obtained but rather used as a motivator to strive toward a goal that is constantly changing. With this mindset we design based on the belief that innovation doesn’t produce the solution for current requirements but rather the requirements for tomorrow’s future.

Manufacturing Capabilities

- Horizontal and vertical manufacturing

- Welding

- B31.1/ B31.3 Welding

- TIG root 7018 -6g

- 6010 root 7018 out -6g

- Tig all out 6g pipe

- Metal Fabrication

- Enclosed Painting

- Pressure Testing

- Electrical Panel building

- Turnkey design, Fabrication, finishing, assembly

- Pressure Testing

Accredidations & Product Certifications

Production

The Next factories has carefully laid out and organized work cells for max efficiencies , with components and parts moving smoothly through our departments and plants from one operation to the next.

Modern production, experienced technique, internal controls, quality assessment procedures and prescribed procedural compliance monitoring, ensures that production department produce only products of the highest quality. We manage all the product phases, from its concept to final production.

Production Departments

- Planning & Sourcing

- Metal Fabrication

- Welding & Brazing

- Electrical Assembly

- Paint & Prep

- Testing

- Quality Control Packaging

Sourcing

- The sourcing strategy of Next Air & Gas intends to establish and maintain long-term relationships with suppliers committed to continuous quality, delivery, statutory conformity and service improvements while ensuring cost competitiveness. This commitment is an expectation of all suppliers that provide products and services to Next Air & Gas. Next Air & Gas will deal with suppliers honestly and with integrity, strive to resolve suppliers’ requests and concerns, communicate requirements and provide suppliers with appropriate support.

- To reduce our carbon footprint, eliminate import costs, and support the U.S. economy, we source as much raw materials and components close to home.

Sustainability

Next abides by the Brundtland Commission’s definition of sustainability: “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

This definition guides us in our strategic and operational choices and in reconciling our business interests with our economic, social, and environmental responsibilities. We seek to operate in ways that secure our long-term economic performance while avoiding short-term behavior that is socially detrimental or environmentally wasteful.

At Next we are committed to operating our business in an environmentally responsible and sustainable manner as we grow. We recognize the urgent need to address climate change, conserve natural resources and promote social equality. We have put our focus on certain areas that matter.

“As part of the Next Generation at Next Air & Gas my goal is to not just implement sustainable practices but to also innovate and find new ways through technological innovation in compressed air and gas dehydration, purification, and generation to provide clean tech products for the future.“ – Kevin F. Zarif

Strategy

We are fortunate to have a clear strategic direction for the years to come as the world mobilizes to transition to a low-carbon economy. The challenge becomes how to best position ourselves in this rapidly evolving field; how to leverage our technological know-how and size and improve flexibility to capture opportunities arising from successively emerging technologies and equipment. To translate this strategy into clarity a series of short-term strategic priorities, have been implemented Our strategic plan is articulated around 5 axes:

- Develop a mindset of sustainability as a foundation during research and development.

- Utilize technologies and IOTC

- Implement key changes in our manufacturing process and facilities to reduce carbon emissions.

- Continuously working to design more energy efficient dryers, generators, and purification systems: innovation and design focus is on efficiency improvements in air treatment, gas treatment, gas generation and gas purification development.

- Reduce waste through our refurbishing and aftermarket programs to extend greater life cycles of our products

Area Of Focus

Climate Change

The issue of climate change is core to Next’s mission of helping our world transition to a low-carbon future by accelerating the production of products that contribute to the renewable gas sector. Our strategy is to meet the growing market demand for energy-efficient and low-emission sources of compressed air & gas dehydration products, to service new customers and maintain strong growth in revenues and operating profitability.

Energy Management

Energy is an input in industrial product manufacturing, stemming mainly from electricity consumption and fuel purchases, so managing how our energy is sourced and how much we consume is part of controlling costs as well as any potential impacts from regulations or taxes on fossil fuels

Human Capital Management

More than 65% of employees work in manufacturing, at our facilities. They face health and safety risks from exposure to machinery and equipment. This is especially the case for welding activities and manipulating very large and heavy metal components. Employee safety is a priority at Next and we continuously conduct health and safety meetings and improvement actions for the betterment of our team.

Fuel Economy and emissions in use phase

The emissions in use phase are an important characteristic of our products, to meet customers’ evolving needs and cost imperatives. It serves as an important competitive differentiator and allows us not only to capture the growing demand for gas generation and air & gas systems but also to capture a growing share of the market. Given the relatively high fixed cost nature of our business, higher growth and revenues can quickly translate to higher profitability.

Materials sourcing

While we design all our products, our manufacturing activities mainly involve the assembly of air & gas dehydration and generation units using components and materials procured from third parties. In this regard, we are dependent on a few suppliers and if they become unable or unwilling to provide us with enough materials and components that meet our quality, quantity, cost, and delivery requirements, we may be unable to obtain suitable substitute materials and components from other suppliers, which would adversely affect our revenue generation and profit margins.

Remanufacturing design and services

The remanufacturing of equipment and components offer opportunities to reduce costs by reducing raw material purchases, generate new revenue streams and strengthen customer relationships by better meeting their need for parts, as well as helping them divert resources from disposal or recycling channels.

NEXT Team

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Next's Product Ecosystem

Next specialize in the mass manufacturing and tailored engineered systems of dehydration, purification and generation for compressed air and gas systems. With supplying supporting filtration, cooling and condensate solutions for compressed air and gas applications.

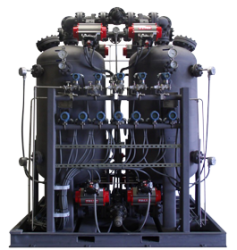

Regenerative Desiccant Dryers

Next Air & Gas offers Heatless, Externally Heated, Blower Purge, and Heat of Compression Desiccant Compressed Air Dryer models in capacities ranging from 5-20,000 CFM (50-10,000 PSIG)

Gas Dryers

Next Air & Gas provides industrial single tower, twin tower regenerative and refrigerated gas dryers for engineered applications in Bio, Natural, Digester, andfill, Seal, Helium, and Carbon gases.

Specialty Dryers

Next Air & Gas is one of the few dryer manufactures today with the engineering capability, capacity and experience to design different types of specialty dryers for sensitive application requirements.

Refrigerated Dryers

Next Air & Gas is an industry leader in the design and manufacture of Refrigerated Compressed Air Dryers. With offerings of non-cycling, cycling, thermal mass, and high temp refrigerated dryers ranging from 5-30,000 CFM (5-10,000 PSIG)

Clean Tech

Next Air & Gas provides engineered end to end systems for air and gas purification and refining.

Gas Generation

Next Air & Gas offers a wide range of industrial Nitrogen and Oxygen generators with purities up to 99.999%

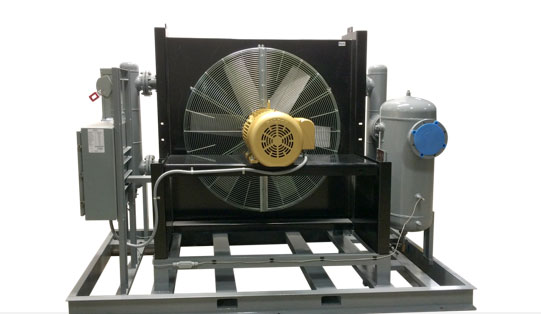

After Coolers

The Next NAC Air Cooled Aftercooler series (130-4,500 cfm) provide economical cooling by utilizing ambient air to cool the hot compressed air from an air compressor. A properly sized aftercooler can remove as much as 60% of the water vapor in compressed air condensation that would flood the piping system downline.

Industrial Process Chillers

The most efficient way to consistently cool high temperature processes like lasers, plasma cutters, welders, and food processing equipment. Reduce costs from water and sewer with fast ROI

Filters & Elements

Next Air & Gas offers High efficiency cast and flange filters from capacities ranging from 45-10,000 CFM and pressures from 232 to 6,000+ PSIG. With coalescing, particulate, carbon and interception elements ranging from 0.01-3 um.

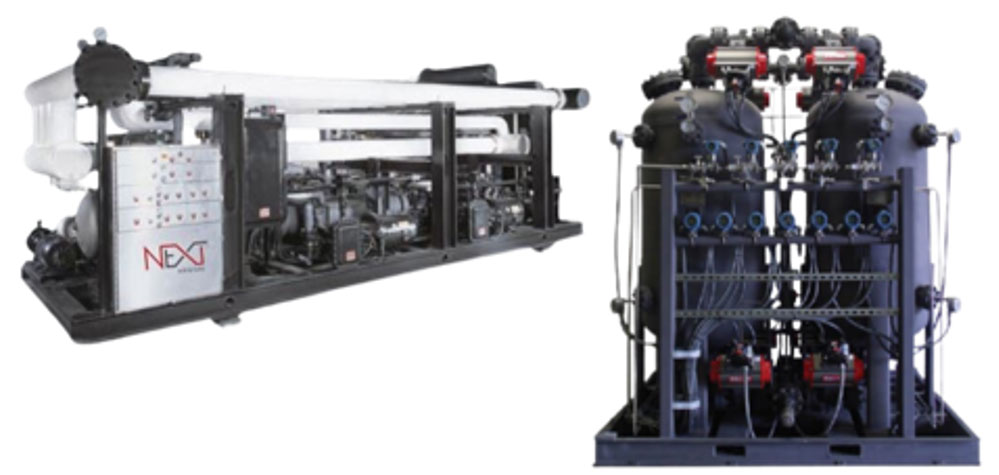

Engineered Systems

Next Air & Gas provides multiple solutions for tailored air and gas systems. In addition to containerized systems and skids.

Cooling Systems

Our Water Saver closed loop cooling system significantly reduces energy costs by removing heat from water cooled machinery, providing consistent temperatures to improve process efficiency. Quick and easy installation.

Condensate Management

Next Air & Gas offer a wide range of, moisture separators, condensate drains and oil & water separators

Private Labeling

Next Air & Gas has private labeled for top leading compressor manufacturers over the years. With our engineering and quality standards ensuring private label customers will receive products catered to their standards and needs.

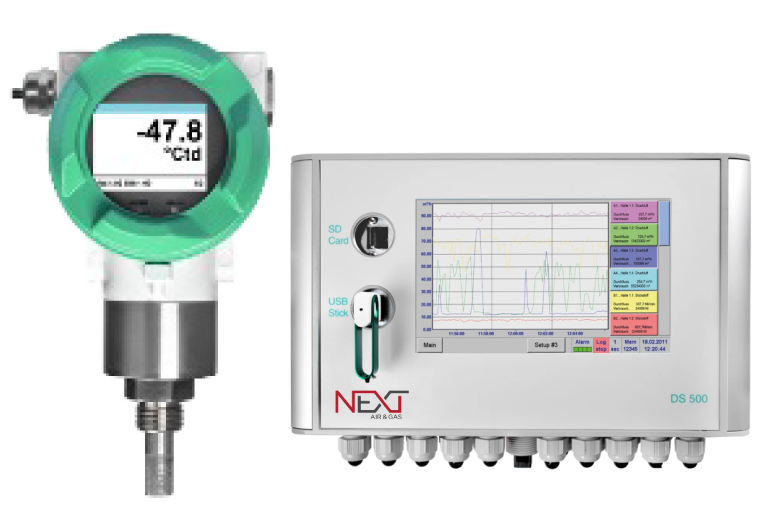

Digital Monitors & Sensors

When dealing with compressed air & gas, measuring small changes in dew point temperature can make a big difference. Benefit from Next’s sensors and chart recorders, that cover a full dew point range for compressed air & gas systems. Increasing the life of your compressed air system, improving process quality and lowering costs is now easier than ever.

Parts

Next Air & Gas products are more than the sum of their parts. Our products are built to last. Next’s genuine parts are the key to their success. We offer a comprehensive library of after market parts for our current and legacy product lines.