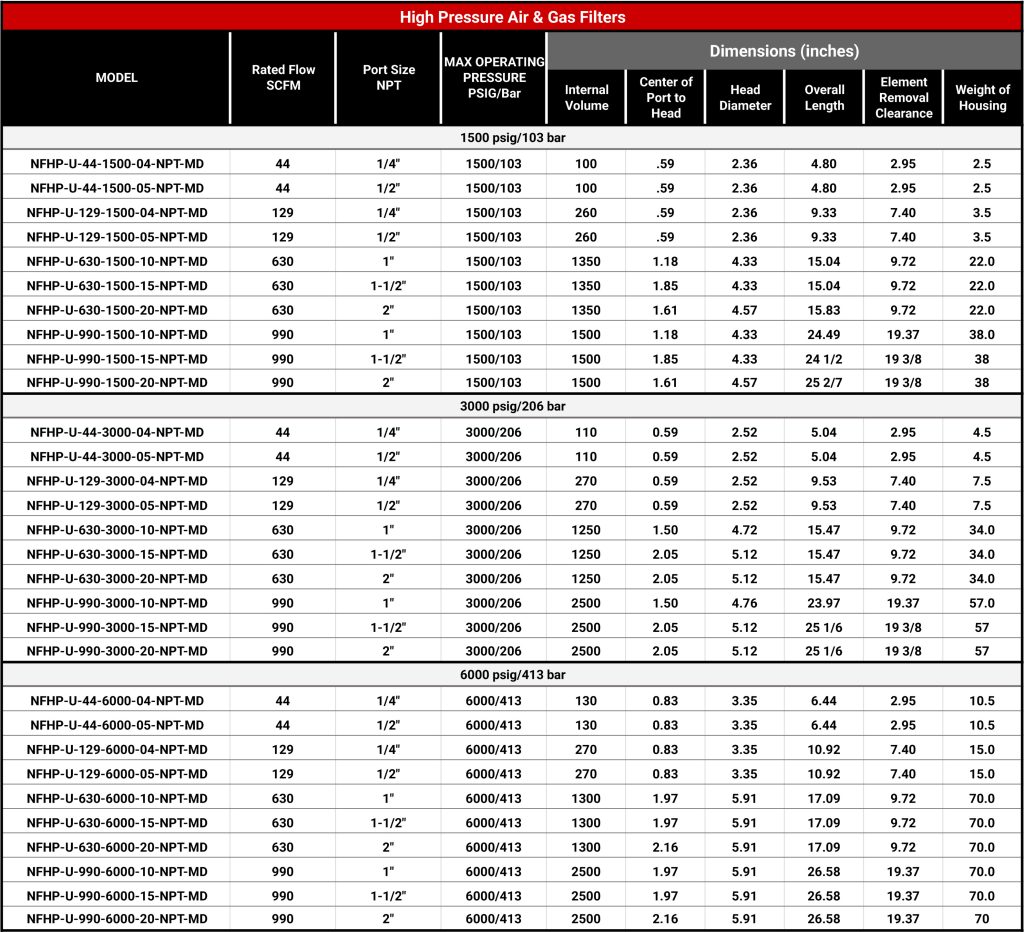

NFHP SERIES Series (44-990 CFM)

High Pressure Stainless-Steel Filtration

(1,500 / 3,000 / 6,000 Psig)

NEXT’s NFHP-U Stainless Steel High Pressure compressed air & gas filters protect sensitive equipment and instruments from the dirt, water, and oil usually found in compressed air and other gases. These filters will remove contaminants at a very high efficiency – up to 99.995% for submicronic particles and droplets. Coalesced liquid drips off the filter element to the drain as additional contamination enters the filter, allowing the filter to remove liquids without the loss of efficiency or flow capacity. These filters are constructed of 316 L stainless steel and are designed to withstand the harshest environments. Specially designed for high pressure compressed air & gas applications. These housings are rated for (1500 , 3000, 6000 psig.) and manufactured to ASME B31.3 & CRN specifications.

The assemblies provide high efficiency filtration with a choice of two grades of robust coalescing & particulate filter elements. The standard element seals are PTFE. These seals are highly resistant to chemicals, making it ideal for applications where the air & gas may contain contaminants or moisture.

Applications

- CNG Filtration

- High Pressure Gas Production

- Sample Process Analyzers

- Supercritical Co2

- Air & Gas production

- Mechanical Seal Filtration

- LNG (liquefied natural Gas) / NGL (Natural Gas Liquids) Filtration

NFHP-U Series Features

- Durable high grade 316 L stainless steel housing construction for corrosion resistance

- Comprehensive range of 316L stainless steel construction, ideal for a wide variety of high-pressure air & gas applications.

- Compact housing design

- Large capacity reservoir

- Head to bowl bore seal ensures greater seal integrity.

- Threaded mounting holes on top of filter head allow each size to be easily panel mounted when line mounting is not an option.

- High flow rates with low pressure drop.

- Complete removal of solid and liquid contaminates from air & gas streams.

- Custom engineered filter media designed to provide low air velocity preventing oil carry over for high efficiency filtration with minimal pressure drop.

- Remove 99.99% of particles of oil, water, and dirt from compressed air and other gases.

- Engineered for energy efficiency – helps reduce operating costs.

- Broad filtration from general purpose to highly stringent applications.

- Optimized air flow design to help increase efficiency and reduce pressure loss.

- Built for reliable and easy maintenance.

Max Operating Pressure

- 1,500, 3000, 6000, psig.

- 103, 206, 413 bar.

Flow Rates

- 44, 129, 630, 990 scfm.

Connections

- 1/4” to 2” npt.

Max Operating Temp Range

- 900° F

- 482° C

Filter Housing Finish

- 316 L Stainless Steel

ISO air quality class (solids, water, oil)

- ISO Class 8573-1:2010

Certification

- ASME B31.3

- CRN

Seals

- PTFE

Micron Rating

- Coalescing (0.01 um)

- Particulate (1 um)

Condensate Drain Type / Size

- Manual Needle Valve drain / ¼” npt

NHPF-U Series Range

* Additional Flows and Pressures available upon request.

NFHP Elements

(NFHP-UE-H) CSX3 Grade – Interior and Exterior Cage for Added Burst Strength

These Elements are designed for heavy coalescing applications. Commonly used in CNG service where added strength is needed due to heavy particulate loading and extremely contaminated coalesced oil. Good to 900°F.Maximum Remaining aerosol content after filtration 0.5 ppm at 70°F (21°C)

Technical Information:

- Materials of Construction: Borosilicate Glass Microfiber with Silica Inorganic Resin with 304 SS Cage

- Type of Application: Heavy Coalescing / CNG

- Maximum Temperature: 900ºF /

- Appearance: White in Color with SS Cage

- Flow Direction: Inside to Outside

- Efficiency at 0.01 Microns

- Seal PTFE

(NFHP-UE-FRS) Five-Layer Stainless Steel

Stainless Steel elements are recommended for filtration of heavily contaminated gases, liquids, polymers, and steam, since they are re-cleanable by back-flushing or ultrasonic cleaning. The elements consist of five layers of precision-woven 316L stainless steel mesh formed into cylinders and sintered together, along one seam.

The five layers offer surface area and depth filtration for removing solids and dropping out liquids. This rigid, durable construction provides precise pore size distribution, flow permeability and lower initial pressure drop than traditional powdered sintered metal elements. As mentioned, the element consists of five layers, with the two outside layers (from both directions) providing pre-filtration, and the inside layer providing the best actual micron rated purification.

Technical Information:

- Material of Construction: Five Layer 316L Stainless Steel with PTFE Seals

- Type of Application: Sample Conditioning, Fast Loop, Steam, and Liquid

- Maximum Temperature: 1000ºF (without seals)

- Appearance: 316L Stainless Steel

- Flow Direction: Both

- Micron Sizes: 0.5, 01, 03,

NFMP-A Optional Features

Additional Pressures +

- 5,000 psig / bar +

- 10,000 psig / bar+

Connections +

- Flanged Connections up to 3”

Filter Housing Finishes +

- Brass

- Aluminum

- Carbon Steel Chrome / Nikel Plated

Condensate Drains+

- NTD-HP: High Pressure Timed Solenoid drain

- NFD: External Zero Loss condensate drain

*(Check with Factory for specific pressures)

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

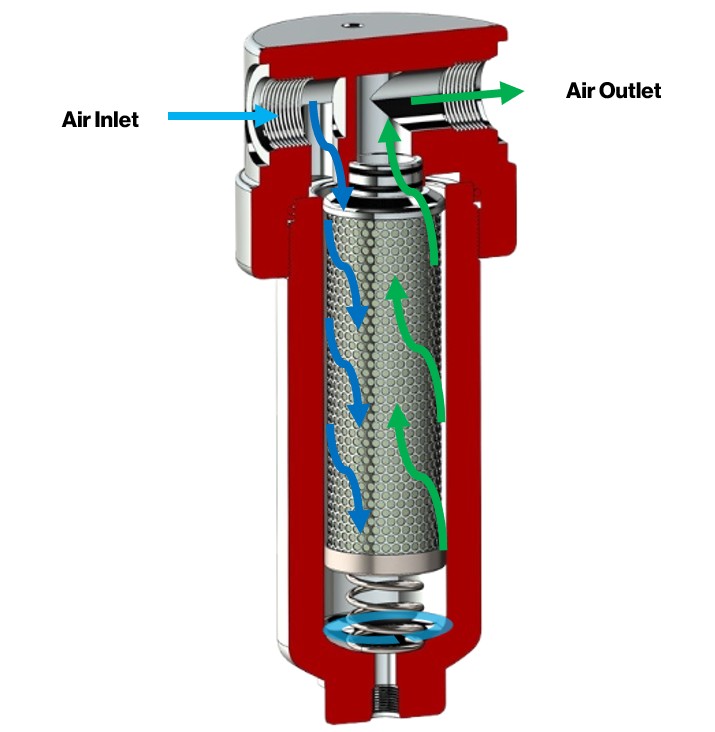

Principle of Operation

- Contaminants are introduced at various stages of the air compression cycle. Removing these contaminants is vital to help ensure part quality, avoid machine damage and protect the air stream.

- Compressed air enters the filter housing inlet. The inlet design helps optimize airflow as compressed air moves into the physical medium of a filter element.

- Then, Untreated compressed air passes through filter material designed for retention of particles such as liquid oil, oil aerosols, dirt and scale.

- Finally, the treated, clean compressed air flows down stream to other inline components or point of use.

- Removed condensate moves from the treated air to be easily drained.

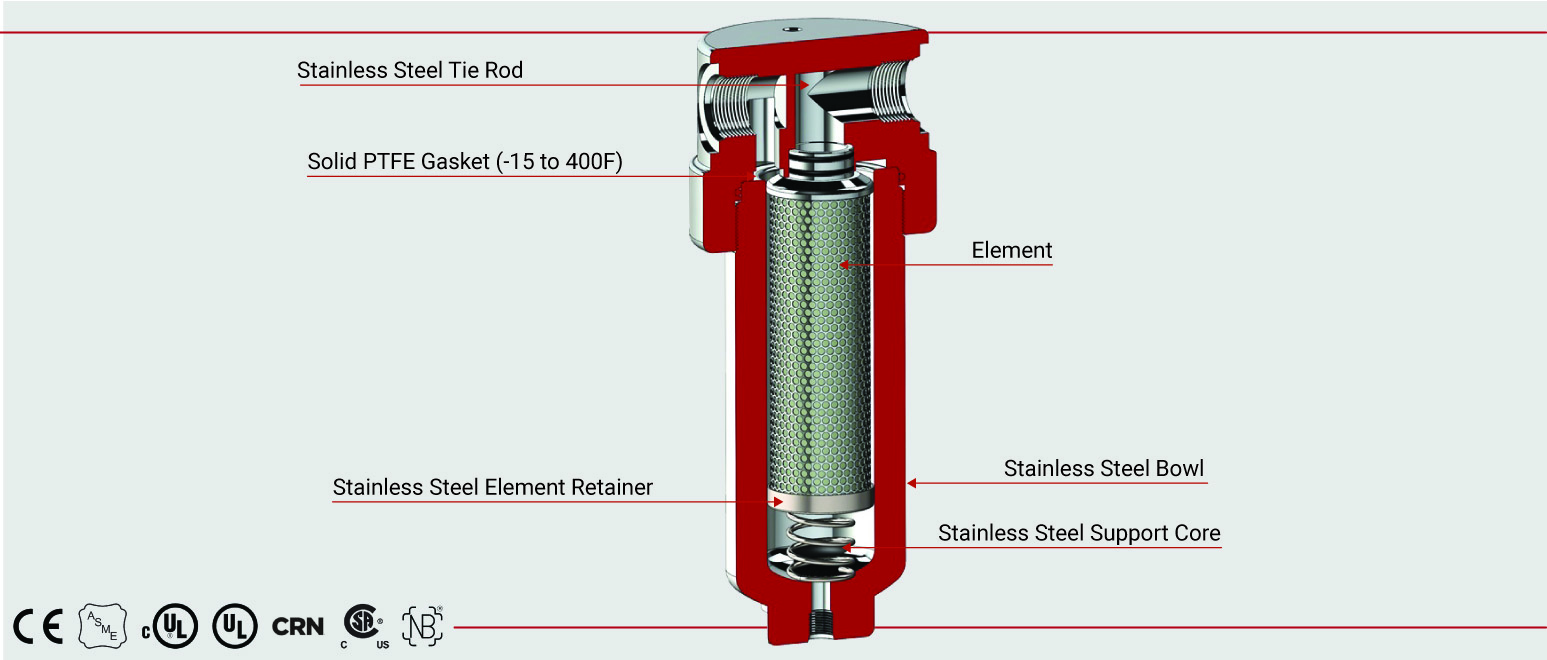

Open View

Next Air & Gas Performance Advantages

The Next range of compressed air filters is designed from the outset to meet current and forthcoming requirements for compressed air quality. Using aerospace technology, Next has optimized the flow path through the housing and element, significantly reducing air turbulence and pressure losses. Providing an optimal flow path is key to reducing pressure drop and system operating costs.

High pressure up to 10,000 psig

Additional Pressures of 5,000 & 10,000 psig @ Max Temp 900 F available in selected flows.

Tie Rod Design

The NFHP Filters employ an internal tie-rod to mount NFHP-E elements in the filter. This style allows for easy post mounting of the elements.

Construction

The housings are made from two parts, and due to an optimized construction, offer low differential pressure at high flow rates.

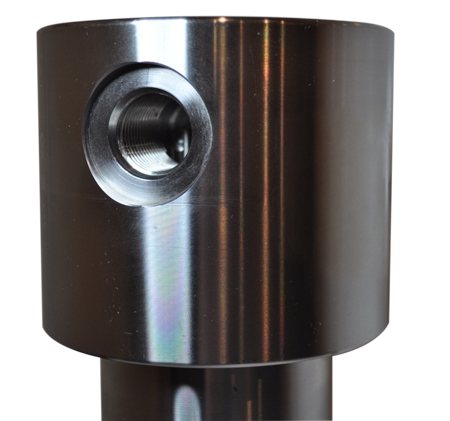

Advanced housing and element design prove a smaller, more compact and light weight filter which is efficient and easy to maintain. All NFHP- U Series filter are manufactured from high grade 316L stainless steel. The NFHP-U housing are perfect for higher pressure applications in corrosive working environments. A threaded collar enables the user to remove the bowl for servicing , without having to remove the drain fitting connections. Critical air & gas processing applications at elevated pressures rely on the NFHP-U-Series to provide clean, contaminant-free gas in corrosive environments. Use this filter for your offshore applications, water fogging, caustic washdowns (food processing) or on high pressure test stands.

*The NFHP-U series are also available in nickel/chrome coated carbon steel, brass and aluminum.

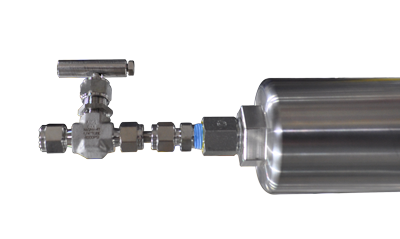

Manual Drain

The Stainless-steel needle valve drain allows the user to drain all oil from the assembly prior to servicing, eliminating possible cross contamination and leaving a cleaner environment.

Connections

The NFHP-U Series assembly has an inlet and outlet design which provides a full-flow stream of air into and out of the housing. Connection sizes and flow rates correlate to capacities and connection port sizes and types and sizes, extra piping or the use of adapters in your application. . Flange connections also available upon request.

Next’s Compressed Air & Gas Filtration

The need to effectively and efficiently dry and filter compressed air & gas cannot be overemphasized. Ineffective purification can lead to system and / or equipment damage and product spoilage. Inefficient purification can lead to unnecessarily high operating and maintenance costs.

With over 40 years of compressed air purification experience behind us, Next has developed an extensive line of air / gas filtration products with a range of efficiencies and optional features to cost effectively meet any of your needs. Our pre-filters and post-filters can be configured to suit the requirements of your specific application.

- Dust Particles (from Ambient air and/or desiccant)

- Liquid Water and Moisture Vapor

- Liquid Oil and Oil Vapor

- Hydrocarbon Vapor

- Rust Particles

- Pipe Scale

- Acidic condensates