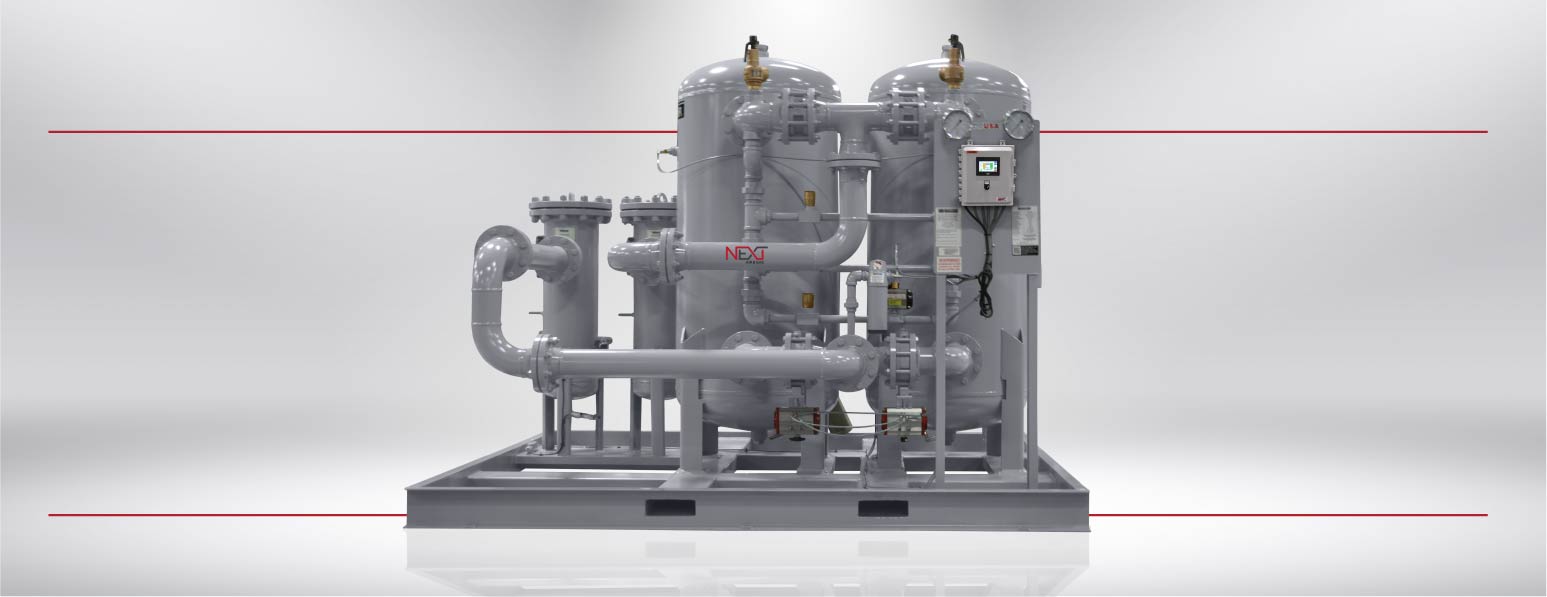

NHOC Series (100-10,000 CFM)

Heat of Compression Regenerative Dryers

Next’s Heat of Compression Dryer Series is designed to use thermal energy from oil free compressors to dry compressed air. The heat is used to regenerate the high-quality desiccant, significantly reducing energy and operating costs.

The NHOC dryer achieves the lowest operating cost, as there is no purge air consumption nor extra electricity use (typically, this is required for low watt high density immersion heaters or centrifugal blowers.) Dew point parameters as low as -40°F can be expected with favorable operating conditions.

Next offers two Heat of compression dryers to choose from.

(NHOC) Heat of Compression Series uses switching valves to achieve dew points of -40°F or lower, regardless of ambient conditions.

(NHOC-S) is a split stream closed loop system that incorporates a cooling cycle for constant pressure dew points of (+10 °F to -4°F) depending on operating conditions. These designs provide a constant stream of moisture-free dehydrated air with little energy consumption. The NHOC series dryers stand out as the most economically and environmentally friendly solution for compressed equipment.

Advantages:

- Achieves ISO 8573.1:2010 Air Quality Class 2 to 4 pressure dew point (-40ºF to +37ºF), contingent upon air compressor discharge temperature

- Requires minimal power, ensuring low operational costs and swift return on investment

- Regenerates desiccant in the off-line tower without needing purge air, eliminating the need for increased air compressor capacity

- Attains low outlet pressure dew points without the use of blowers or booster heaters

- Features a fully packaged, skid-mounted design for effortless installation

NHOC Series Features

- 7” Color touch screen HMI interface

- ASME/ CRN code welded pressure vessels

- Fail safe design in case of power failure

- Inlet/outlet pressure gauge

- Inlet/outlet temperature gauge

- Desiccant fill & drain port

- Activated Alumina desiccant

- Stainless steel desiccant outlet screen

- Stainless steel desiccant inlet screen

- Non lubricated switching valve

- Purge exhaust valves

- Safety pressure relief valves in each tower

- Tower pressure gauge

Tower temperature gauge - Fully automatic operation

- Hot air line insulation with safety aluminum jacket

- Tower insulation with safety aluminum jacket

- Power on/off switch

- Power on indicator

- Tower operating status lights

- Inlet valves open/closed failure alarm

- Separators drain failure alarm

- Water cooled aftercooler

Standard operating Voltage:

- 460V / 3 PH / 60 HZ – Standard

- 575V / 3 PH / 60 HZ – Optional+

- 400-380V / 3 PH / 50 HZ – Optional+

Pre & Post Filtration (Optional+):

- Post-filtration grade μm 1.0

- Pre-filtration grade μm 0.01

Pressure Vessel Certification:

- ASME, CRN (NHOC-125-2,500) All Provinces

Min/Max inlet air temperature :

- 220/400 ° F

- 104/204 ° C

Design Pressure:

- 200 Psig./ 13 Bar (100-1,600 CFM )

- 150 Psig./ 10 Bar (2,000+ CFM)

Electrical Enclosure NEMA Rating

- NEMA 4

Min/ Max Operating Pressure:

- 80 / 150 Psig

- 5.5/10.3 Bar

Control Panel Certification

- UL, CUL,

- CSA- Optional+

Standard outlet pressure Dew Point

- Up to -40° F / C (NHOC)

- (+10 °F to -4°F/-12 to 20°C (NHOCS)

Average Purge Air

- 0% Standard

- 2-3% Split Stream

Controller

- 7” HMI Touch Screen Controller (Standard)

- 7” Allen Bradley Touch Screen Controller – (Optional+)

ISO Air Quality Class

- ISO 8573.1:2010 Class 2 to 4 pressure dew point (-40ºF to +37ºF)

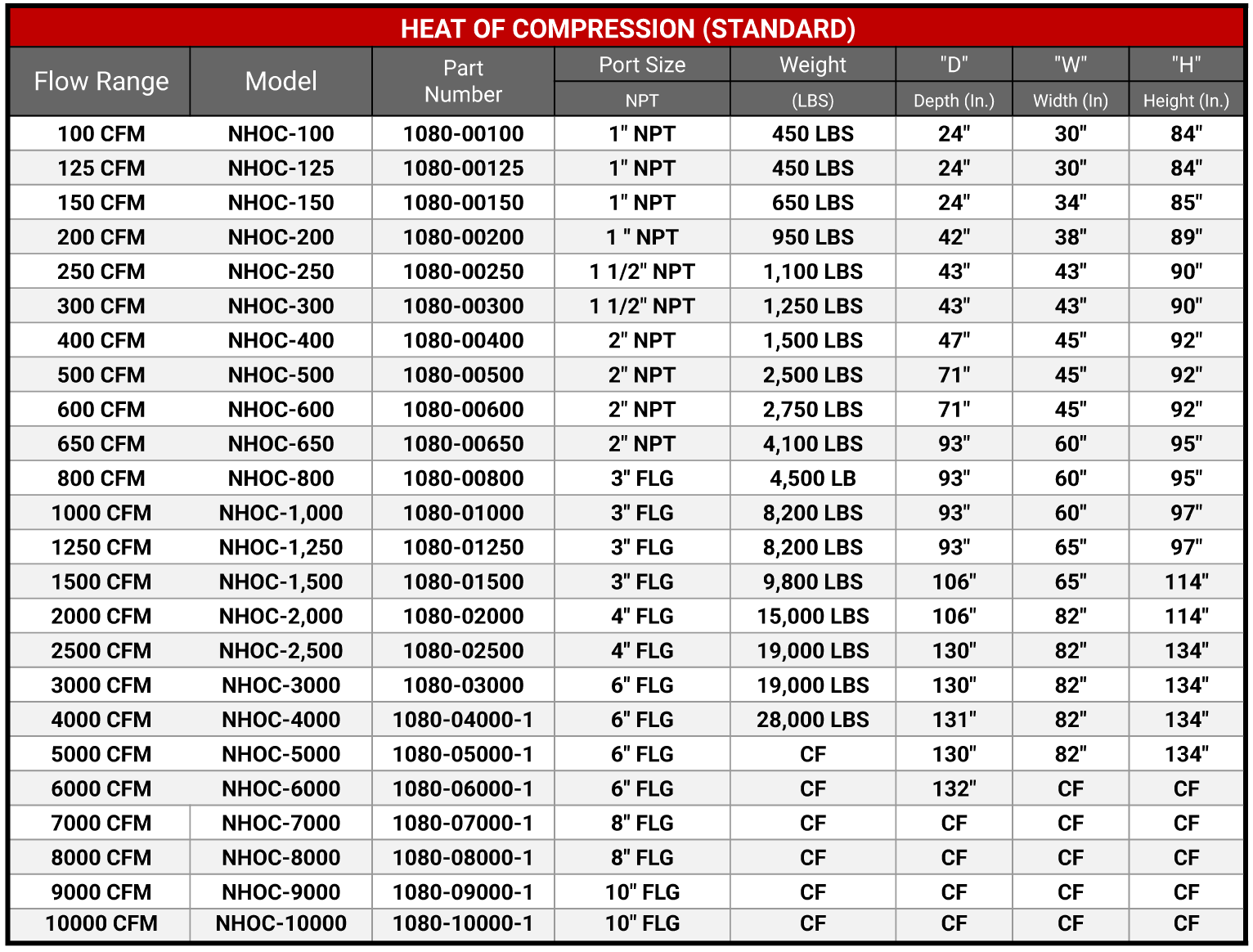

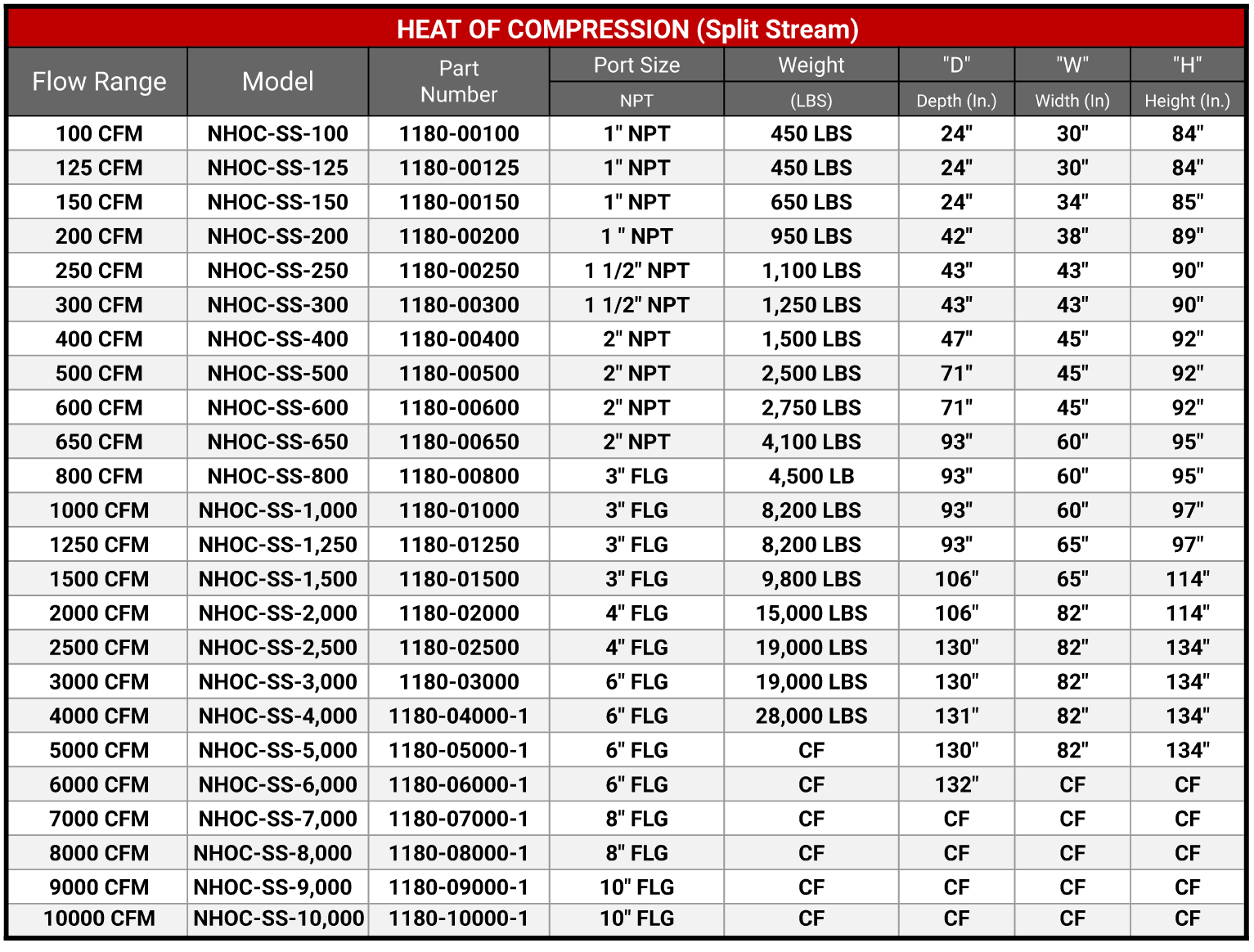

NHOC Series Models

NHOC Optional Features

ALTERNATE VOLTAGES+

- ALT-V-5: 575 VOLTS / 3 PHASE / 60 HZ

- ALT-V-6: 400-380 VOLTS / 3 PHASE / 50 HZ

CONSTRUCTION+

- NYM: NO YELLOW METAL

- CSA: CANADIAN STANDARDS ASSOCIATION

- BTS: BUILT TO SUITE

- IOPG: INLET-OUTLET PRESSURE GAUGE

- IOTG: INLET-OUTLET TEMPERATURE GAUGE

- TTG: TANK MOUNTED TEMPERATURE GAUGE

- VMI: VISUAL MOISTURE INDICATOR

- SST: STAINLESS STEEL CONTROL AIR TUBING

- CR: CONTROL LINE PRESSURE REGULATOR

- EPH: ELECTRICAL PANEL HEATER

- AC: After Cooler

ELECTRICAL ENCLOSURE+

- N12: NEMA 12 ELECTRICAL ENCLOSURE

- N4X: NEMA 4X STAINLESS STEEL

- N7: NEMA 7 EXPLOSION PROOF

CONDENSATE DRAIN+

- FD: CONDENSATE FLOAT DRAIN

- EZLD: ELECTRONIC ZERO LOSS DRAIN

- MZLD: MECHANICAL ZERO LOSS DRAIN

- HPTD: HIGH PRESSURE TIMER DRAI

PACKAGES +

- LAP:LOW AMBIENT PACKAGE

- SZ:SUBZERO PACKAGE

- RS: RENTAL SKID

- HP: high pressure

- ZP: ZERO PURGE

- SH: Steam Heated packaged

- TH : Trim Heater

DEWPOINT & DIGITAL MONITORING+

- DCC+DDP: DEMAND CYCLE CONTROL +Dew Point Sensor

- DDPM-40: DIGITAL DEW POINT MONITOR (-40° F/ -73° C)

- DDP-40: DIGITAL DEW POINT SENSOR (-40° F/°C)

- DDP-100: DIGITAL DEW POINT Sensor

- DCA:DRY CONTACT ALARM

- ESS:EMERGENCY STOP SWITCH

- RSS: REMOTE START / STOP

BYPASS +

- 3VBP:THREE VALVE BY-PASS

- 9VBP:NINE VALVE BY-PASS

FILTRATION +

- MF: MOUNTED FILTRATION

- SP-F: SPECIAL FILTER CONFIGURATION

- FS: FILTER SKID (ISLAND)

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Principle of Operation

NHOC series – Hot compressed air from the air compressor (350°F or higher) enters the reactivating vessel. After absorbing moisture from the desiccant, the saturated air exits the tower into the aftercooler, where it is cooled (100°F or lower) and liquid water is removed. Cooled air then enters the drying vessel to be dried to its final dew point. Pressure dew point of the NHOC design depends on the ambient temperature and may vary from summer to winter. Also, for a short time during thetower change-over, a small spike in dew point may occur until the desiccant temperature stabilizes.

NHOC-S series – – Hot compressed air from the air compressor (350°F or higher) enters the reactivating vessel. After absorbing moisture from the desiccant, the saturated air exits the tower into the aftercooler, where it is cooled (100°F or lower). It then goes to the filter separator, where liquid is removed through the drain trap. This cooled air enters the drying vessel to be dried to its final dew point. At the end of the compressor heating cycle, hot air is directed to the aftercooler and a small amount of cold, dry air (2% – 3%) is passed through an adjustable orifice and directed through the reactivating tower to remove any remaining moisture adsorbed by the desiccant and vent it to the atmosphere. At the end of this cycle, the reactivating tower will be pressurized again for cooling cycle and the cool air will be diverted to the other tower to cool its desiccant bed prior to tower shift. This provides a low consistent pressure dew point.

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

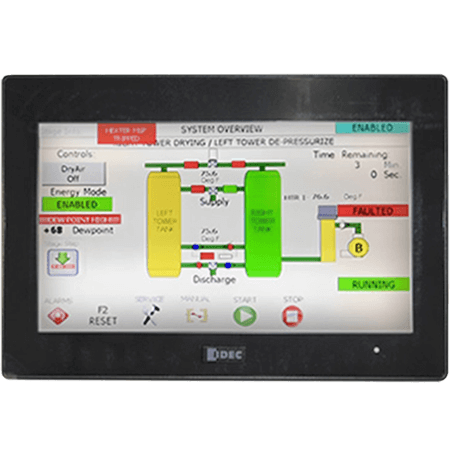

HMI Touch Screen Interface

The entire drying/ regeneration cycle is controlled by a Micro-Logix programmable logic controller (PLC), among the most reliable controllers available. The plc is supplied with a 7″ Siemens touch screen HMI display which, among other items, will provide the operator with the following information.

- Indicate alarm when a system fault is detected and identify the specific fault

- Indicate status of each vessel (drying, regenerating, or in standby)

- Indicated time remaining of each phase of the cycle

- Housed in NEMA 4 electrical Enclosure

Digital Dewpoint Transmitters Optimize Operations

NEXT’s FAN-500 and 510 are the ideal dew point sensors for monitoring dew point changes for our desiccant dryers. If your needs include a set dew point of -40° F or -100° F, NEXT’s range of dew point sensors has it covered.

- Modbus-RTU Interface

- Higher Resolution of Sensor Signal Through Improved Evaluation Electronics

- Integrated Display (Fan-500)

- Pressure-tight up to 5,000 psig./350 Bar (special version)

- Extreme Long-Term Stability

- Quick Response Time

Quality Desiccant Media

Next Air & Gas uses a mixture of adsorption media in its heatless range of desiccant dryers to achieve consistent dewpoint. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application. The long lasting, high crush strength media has a very high surface/volume ratio. Beaded activated alumina is used as the adsorption media in heated desiccant dryers. The beads exhibit a very high internal surface area and high moisture separation efficiency. Each lot of desiccants is thoroughly tested for density, moisture content, abrasion resistance, surface area, mesh size and granule strength to assure that it meets strict design requirements.

Butterfly Valves for Precise Control

These versatile, high-performance butterfly valves are used by Next Air & Gas to provide you with precision control and complete bubble-tight shut off. The digitally controlled actuators provide an easy PLC interface and feature fast response time. The tongue-and-groove seat design feature ensures complete isolation of flowing media from the body and stem. Rugged and reliable, these valves are designed to provide years of trouble-free service.

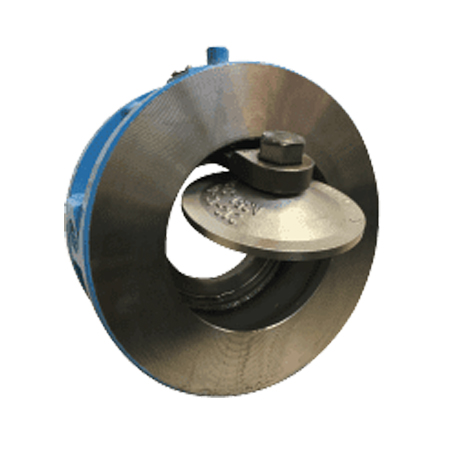

State-of-the-art Check Valve

Check valves are used at the dryer outlet and on the hot air regeneration lines. They are designed with large ports to minimize pressure loss. Outlet check valves incorporate a stainless-steel disc and O-rings while hot air regeneration valves utilize a metal-to-metal seal to withstand elevated temperatures. High Temperature with a water-combination swing check valves are flow activated. The elliptical shape of the inlet port accelerates the inlet media through the valve. The disc’s angle and shape allow the air to travel faster around the disc, thus creating lift like an aircraft wing, and opens the valve in the full position even at a low flow rate.

Zero Loss Condensate Drain

- Fully automatic operation. No timer or manual settings.

- Pneumatically operated, avoiding the use of an electrical connection

- Low profile designs The vertical operating height allows to fit where other larger units cannot.

Purge Exhaust Mufflers

- Utilized on the purge exhaust to keep noise levels to a minimum

- Complies with OSHA Standards by keeping noise tolerance at <85 dBA on a time weighted average.

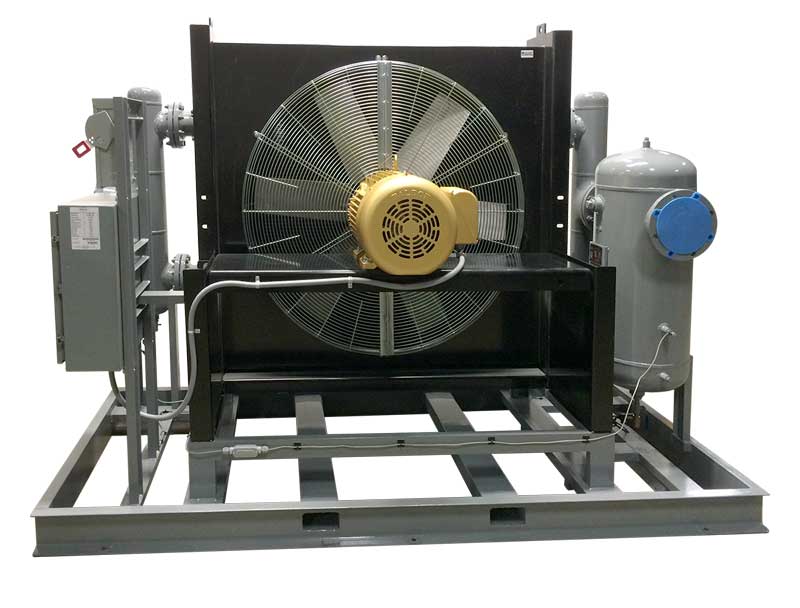

Integrated After Cooler

- Advanced technology designed for maximum heat transfer.

- Durable aluminum plate core designed to save space and minimizes energy usage

- Corrosion resistant construction

- Horizontal airflow

- Rugged bar & Plate design

Moisture Separator

- ASME Certified

- Maximum efficiency with minimal Pressure drops

- Designed centrifuge and high efficiency fixed impeller with “O” ring seal and anti -re-entrainment disc to ensure moisture free air down-stream.

Pressure Vessels

BHL desiccant vessels have been designed with a wide diameter for a large cross- sectional flow area. This results in a low flow velocity which minimizes both pressures drop across the bed and attrition of the desiccant itself. The Vessels incorporate the flowing additional features:

- Stainless steel inlet and outlet air diffusers for even flow distribution

- Stainless steel bed support on units above 3,000 scfm

- Desiccant fill and drain ports

- 1/16” corrosion allowance

- Operating pressure gauge on each vessel

- Pressure relief Valve on each vessel

- ASME / CRN Certified

Booster Trim Heaters

- As an additional option a booster trim heater can be added. The boost of heat automatically energizes the system if the regeneration temperatures not adequate.

Shell & Tube Heat Exchanger

- ASME Certified

- Brass shell & Baffles

- Copper Tubes

- Forged Brass End Hubs

- Cast Iron End Bonnets

Certifications

PREMIUM PLEATED & WRAPPED COMPRESSED AIR FILTERS

Next offers superior filtration from 1 micron to 0.01 micron, and connections from ½” NPT to 10” FLG. Next Filters are engineered to be efficient under any parameter. Next elements offer a durable element construction with an efficient drain layer to ensure continued performance after optimal element change periods.